ZX-C2 three heater hot air IR manual repair laptop PS xbox bga rework station

| Type:Other | Place of Origin:Guangdong China (Mainland) | Brand Name:Zhenxun | Model Number:ZX-C2 |

| Voltage:220V | Current:10 A | Rated Capacity:4000 W | Rated Duty Cycle:300 |

| Dimensions:L550*W530*H550mm | Weight:50 KG,Approx. 50kgs | Usage:remove and replace bga ,chipset,IC,QFN,CSP, QFP,POP | PCB Size:Max L330*W320mm |

| PCB Thickness:0.1~5mm | Temperature Control:K thermocouple PID Closed loop | PCB Positioning mode:Outer | Bottom preheat:Infrared 2400 W |

| Top heater:800 W | Bottom heater:800 W | Power supply:Single phase 220V,50/60Hz,4.0KVA | Dimension:L550*W530*H550mm |

ZX-C2 BGA rework station, SMD rework station

Features:

1.Using three independent temperature control, more accurate;

2.Upper and bottom heater using good material, can accurately regulate hot air flow and temperature , high temperature generated breeze, third with far infrared heating plate to preheat.

3.The first, second and third-zone with 8 segment temperature up (down)+8 segment constant temperature control, can store 10 groups temperature curve;

4.First zone and second start running temperature curve at the same time, third zone start running temperature rise and drop at the same time with first and second zone;

5.The first-, second-zone with over temperature protection design;

6.After remove and welding, using high-volume fan to cool the PCB board, prevent deformation of PCB board and ensure the effect of welding;

7.The first temperature zone can be front and back, up and down adjustment and 360-degree rotation, convenient to operate;

8.The second temperature can adjust according to different PCB board appearance and components, prevent collision with PCB lower plate components;

9.The third zone can be moved right and left, suitable to repair large BGA,CBGA and BGA in partial side of PCB board;

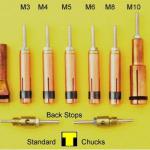

10.Equipped with a variety size of hot-air nozzle, or made according to special requirements, free rotation of hot air nozzles;

11.Adjustable PCB jaw, to prevent collision with the components;

12.Adjustable high-temperature resistance bracket, position rack designed to protect against hot;

13.After BGA remove and welding have voice alarm function;

14.Hand-held vacuum suction pen take BGA, convenient reliable and durable

| PCB Size | Max L330*W320mm |

| PCB Thickness | 0.1~5mm |

| Temperature Control | K thermocouple PID Closed loop |

| PCB Positioning mode | Outer |

| Bottom preheat | Infrared 2400W |

| Main (Top+bottom) heater | Hot air 800W+800W |

| Power supply | Single phase 220V,50/60Hz,4.0KVA |

| Dimension | L550*W530*H550mm |

| Weight | Approx. 50kgs |

| Packaging Detail:Standard wooden package1 PC machine per one boxPackage size: L660 * W620 * H700mm Package weight: 60KGS |

| Delivery Detail:1 day |