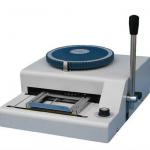

ZX-5375B+37KF Auto Crease folder/Creasing and folding machine

| Condition:New | Automatic Grade:Automatic | Place of Origin:Zhejiang China (Mainland) | Brand Name:INNOVO |

| Model Number:ZX-5375B+37KF | Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | Crease in one pass:1-16 / sheet |

| Min crease spacing:0.2mm | Speed:20-30sheets/min (A4 /1 crease) | Number of program:16 (with named programs via keyboard) | Thickness:from 100gsm to 350 gsm |

| Length:Min140*140 mm Max 900*370 mm (L*W) | Folding types:6 kinds(Single/Zigzag/Gate/Letter/Fold out/Double parallel | Folding times:2times | Distance between two folds:Min 70mm Max 300mm |

ZX-5375B+37KFAuto Crease folder

Why Fold

Fold make the print product into wanted size and easy to hand, and more beautiful.

Why crease?

On digital print, the paper grain will need to be gently broken to allow a clean fold, otherwise unsightly cracks will appear. The bar creaser allows you to gently do this to allow for a perfect crack-free fold.

What Auto creaser folders can do?

Auto crease folders offer a flow job of crease and fold,the bar crease die that move upward/downward is specially designed to touch the paper, which will gently make a clear crease, but will not break the paper fiber inside or any ink printed on.And then the knife folder will make the paper into wanted fold pattern,becutifully and in neat.

Crease in one pass: 1-16 / sheet

Min crease spacing: 0.2mm

Number of program: 16 (with named programs via keyboard)

Speed: 20-30sheets/min (A4 /1 crease)

Sheet processing time: 25sheets/min(A4 /1 crease line single fold)

Thickness: from 100gsm to 350 gsm

Length: Min140*140 mm Max 900*370 mm (L*W)

Folding types: 6 kinds(Single/Zigzag/Gate/Letter/Fold out/Double parallel)

Folding times: 2times

Distance between two folds: Min 70mm Max 300mm

Beside,Linear perforationis also optional

Crease and fold is under the control of software, touch screen, sensors; executes with precise step motors, rollers, the screen interface is friendly and operation is easy.

Description

This model is consist of 5375B and 37KF.

5375Bis a slid in creaser and 37KF is as above

In hardware,they are not connected,but in software,they are connected with signal cable so that you can operate with either of the screen,no matter it is on 5375B or in 37KF.

Optional parts

Different tools: In order to fulfill different requirement

Outfeed convyor:

OUTFEED CONVYOR UNIT:

It hook and is supported at the side of fold unit, to receive output fold product in neat and perfect shapes by the conveyor system.

Motor in the unit is pluged in the software and enabled/disabled with the running /pause operation. The speed that controls the shingle ,is controlled by a knob on the unit.

Press wheel runs on the unit, driven by the belt that driven by motor, to enhance the folding work. The wheel position is adjustable ,because it have to be at the position where the product will reach when it just come out, or they can not be neat.

| Packaging Detail:wooden case |

| Delivery Detail:15days |