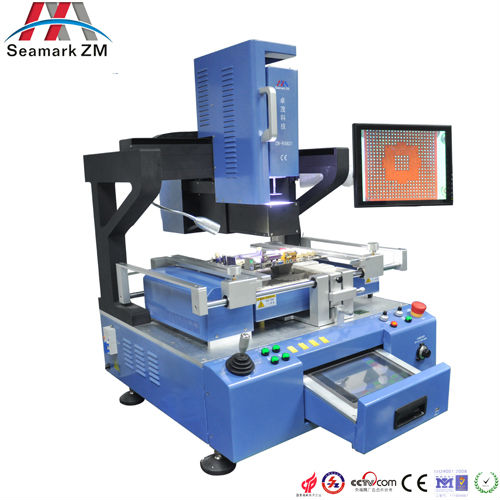

ZHUOMAO SEAMARK ZM Automatic Vision ZM-R6821 Bga Rework Station

| Type:Other | Place of Origin:Guangdong China (Mainland) | Brand Name:Seamark ZM/ zhuomao | Model Number:ZM-R6821 |

| Voltage:220V | Current:24 | Rated Capacity:N/A | Rated Duty Cycle:N/A |

| Dimensions:N/A,L800*W700*H1000mm | Weight:85kg,130kg | Usage:repair BGA/SOCKET, desoldering, soldering.etc,all types bga chipsets | Certification:ISO CE FAMOUS BRAND CHINA |

| After-sales Service Provided:Overseas service center available | color:black | Power consumption:5800W | PCB size:22*22mm 400*450mm |

| level:high automatic | Camera magnification:10x to 100x | temperature control:IR and hot air combine | positiong:laser positiong |

ZHUOMAO SEAMARK ZM Automatic alignment ZM-R6821 Bga rework station

repair laptop, desktop, vga, cup, bga, xbox, ps3 , all types of chipsets

Specifications

1 Power consumption 5800W

2 Top heater 800W

3 Bottom heater Infrared plate 4200 W - Nozzle 800 W

4 Power requirement Single phase AC 220V ± 10% - 50 Hz – 5.8 kVA

5 Dimensions L800×W700×H1000mm

6 Positioning V-clip PCB clamping | 10~20 μm X-Y table adjust.

7 Temperature control Imported K-type thermocouple (Closed Loop) ±3-5°C

8 PCB size 22×22mm to 400×450mm

9 Camera magnification 10x to 100x

10 Weight 130 kg

Features:Features:

1. This touch screen controlled desktop rework station is the most compact of our high range equipment. Password protects the data. The temperature profile chart can show 7 profiles at any time.

2. With 5 high precision thermocouple, the temperature can be precisely controlled within a 2°C range by the PLC.

3. With 6 programmable temperature zones, preheat, ramp up, reflow, solidification and cooling can be precisely adjusted.

4. 100 profiles can be recorded within the machine and flexibly created and modified through the touch screen interface.

5. Heating and placing head’s unique combined design, allows flawless placing and soldering. X,Y and Z axis are driven by step-motors. The software can remember 100 groups of coordinates.

6. The 3 temperature zones are controlled independently by the software. Preheating the PCB with infrared plates can avoid deformation and guarantees precision of soldering.

7. Use a powerful cross-flow fan to cool PCB rapidly to prevent it from deformation and ensure the welding effect.

8. Use a V-groove equipped with a flexible fixture for PCB positioning to protect the PCB.

9. The touch screen controls the upper heating system and the optical device. Is is very easy to operate.

10. The top and bottom heating head can move freely on the infrared plate so that BGA can be repaired on different areas of PCB.

11. The machine is equipped with Japan imported vacuum pump.

12. The CCD camera can simultaneously observe the component picked up by the nozzle and the pad on the PCB. The color sensitive focal positioning system can achieve a matching accuracy of 10 to 20 µm.

13. The operator can supervise the process on a split screen 17” monitor.

14. The high degree of automation achieved with this model minimizes the risk of human error.

15. This equipment completely meets the requirements of lead-free process.

Our Factory

Showing Room

Assembling line

PACKING

EXHIBITIONS

Certificate

We are biggest bga rework station manufacturer in china.

For more details, please contact with us.

Training and Warranty:

life-time free training of operation and maintenance

warranty: lifetime warranty. the 1st year is free, ONLY spare parts charged after the 1st year. Reply within 24hours, 6 days/week.

training and warranty can be from the overseas local office or Zhuomao Shenzhen head office directly or the third party.

| Packaging Detail:wooden box packing |

| Delivery Detail:3 weeks |