zhangjiagang plastic granular extruder production line

| Condition:New | Type:Granulating Production Line | Capacity:Maximun 1000kg/hr,400-550kg/h | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:PURUI | Model Number:ML series plastic granular extruder production line | Material:PP/PE | Screw Design:Single |

| Voltage:380V/415V/220V 60HZ/50HZ | Power:132kW | Dimension(L*W*H):5m*3.2m*3.9m | Weight:8 ton |

| Certification:CE&GMC certificate | Warranty:one year plastic granular extruder production line | After-sales Service Provided:Engineers available to service machinery overseas | Machine name:zhangjiagang plastic granular extruder production line |

| Model:ML130 | Motor power:132kW | L:D:30:1 | Heating method:electric heating |

| Cooling method:forced wind cooling | Cutting method:water-ring rubs surface pelletizing | Guarantee period:one year | Delivery:45 working days after we get deposit |

zhangjiagang plastic granular extruder production line

1.plastic granular extruder production linewith high effectively exhaustin,filter

Features:

1.High efficiency and high performance

2.Material is cut ,pre-dried,pre-heated,pre-homogenized and compacted in the shredding drum.

3.Many material can be processed directly without need of the upstream pre-shredding,resulting in a dramatic reduction in operational costs.

4.Less power consumption cost per kilogram,high throughput,reduced floor space occopation and operator attendance.

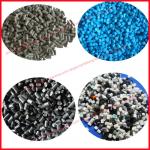

2.Machine photos of plastic granular extruder production line for your reference:

You can see from this photo that we allocated aheating exchangerto this machine.

With the heating exchanger, the cycling water in the water tank can get cooled which is used for cooling the pellets comes out from the cutting head. It's a good way to cooling these pellets and get a effective effect.

A vibration can be chosen, With avibration, the pellets can be selected automatically if you have a high demand for these pellets.

3.Main Technical Parameter for plastic granular extruder production line like this:

Normal type:

High output,low consumption:

4.Load the container

In order to insure the machine can safely arrived to customer's destination without damage so we do the following steps

film packing&wood packing→forklift (truck)→load into the container→fix→seal the container

WELCOME TO OUR FACTORY

Company image

.

Productin field

5.WE ATTEND Chinaplas every year and this is the photo we took with our clients

6.Certificate we've got

CE certificate

GMC Certificate

Choose PURUI, Choose your most reliable supplier. We are ready looking forward to hearing from you and cooperate.

| Packaging Detail:plastic granular extruder production linefilm package, wood tray on the foot of the machine,no recycling |

| Delivery Detail:plastic granular extruder production line:40-50 working days |