Z94 series automatic wire rod nail making machine from Dongxing Brand

| Place of Origin:Henan China (Mainland) | Brand Name:Dongxing | Model Number:Z94-3C,Z94-4C,Z94-5.5C | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Item:z94-4c nail making machine | Raw materials:wire rod | Diameter of nail:2.8-4.5mm |

| Length of nail:50-100mm | Capacity:4kw | Dimension:2.2X1.6x1.65m | Weight:2ton |

| Nail making speed:260pcs/min | Color:green | Package:free wood case |

Z94 series automatic wire rod nail making machine

Introduction

Nail making machine is a production facility which used to make nail.

It also named waste rebar nail machine, nail making machine can change waste rebar to nail, the invention is very environmental protection, at the same time, help many people become rich quickly.

Advantages:

Nail making machine gives priority to economic and practical applicability, its advantage is high technology, easy handle, little motive powder, save energy, stable function, and it has little volume, convenience to move, low noise, low powder consumption, easy to install etc features. That’s the reasons of why many companies, individual, family, laid-off worker and peasant like it.

Features

1 .Both of the scrap iron wire and the new steel rod can be used to make nails.

2 .This nails machine can feed the materials automatically.

3 .This nails machine has the features of high speed, low noise, less impact and good continuity.

4. All the main components are made of quality steel, such as shaft, cams and gear.

5.The profit using wasts steel is 5 times of that using finished steel.

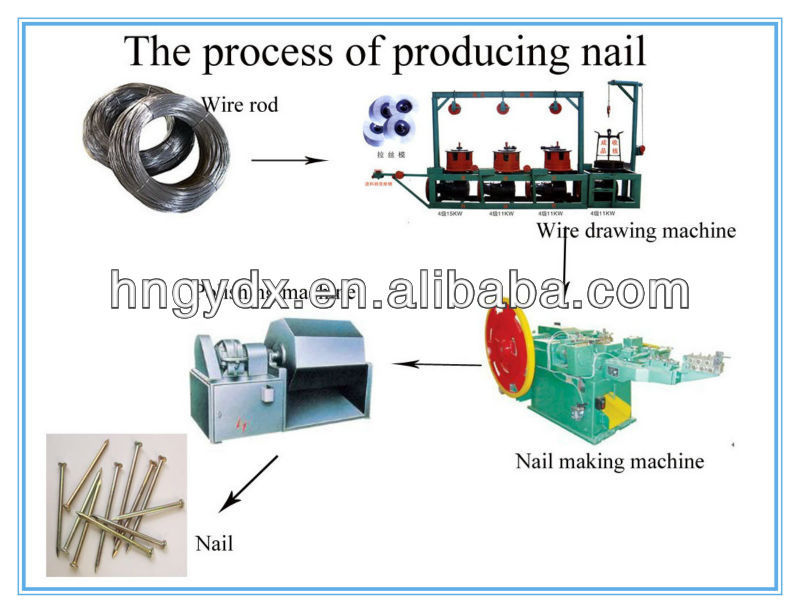

Processes:

Waste rebar---A or B wire drawing machine---nail making machine(you can choice one type)---polishing machine---finish nail---packing

1, wire drawing:

You should choice which rebar do you need to make nail after you buy the nail making machine, such as new rebar, new steel wire, waste bar and so on. Waste bar is inconvenient when wire drawing, it’s slow than new rebar, but waste bar cost is very low, then the profit is very good. If you use new steel wire, the speed of produce nail is quickly.

2, nail making:

Put the wire in automatic wire feeder head pulley, and adjust the size of nail in advance.

3, polishing:

Using polishing machine polishing the semi-finished nail, add some saw powder, paraffin, oil and other material in the machine.

4, packing:

User can packing the nail as their need.

Nail making machine technical data:

| Serial number | Product name | Model | Main purpose | diameter of wire | Power(kw) | Weight(kg) | Designed output |

| 1 | Nail making machine | Z94-5.5C | Manufacturing 4-6 inches of nails | 3.8-5.2mm | 5.5 | 2300 | 200pcs/min |

| 2 | Nail making machine | Z94-4C | Manufacturing 2-4 inches of nails | 2.8-4.5mm | 4.0 | 2000 | 260pcs/min |

| 3 | Nail making machine | Z94-3C | Manufacturing 1.5-3 inches of nails | 1.8-3.1mm | 3.0 | 1000 | 300pcs/min |

| 4 | Nail making machine | Z94-2C | Manufacturing 1-2 inches of nails | 1.2-2.8mm | 2.2 | 800 | 350pcs/min |

| 5 | Nail making machine | Z94-1C | Manufacturing 0.5-1 inches of nails | 0.9-1.8mm | 1.1 | 500 | 450pcs/min |

The process of producing nails

Wire drawing machine

Nail making machine

Nail polishing machine

Spare parts

Nail knief

Punch pin

Contact way:

| Packaging Detail:pallet or free wooden case |

| Delivery Detail:15days after receipt front money |