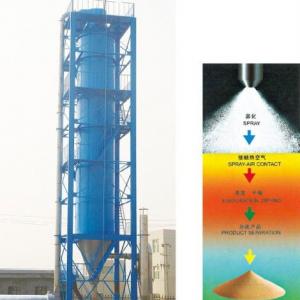

YPL Calcium chloride dryer

| Product Type:food, chemical, pharmaceutical drystuff industry | Place of Origin:Jiangsu China (Mainland) | Brand Name:Jinling | Model Number:YPL |

| certificate:ISO9001:2008 | material:carbon steel, SS304 | heating resource:steam,oil,gas,coal | amount of evaporated water:50-1000kg/h |

| overall size:1600*8900-4600*22500mm | pressure of pump:0.5-8mpa | power:8.5-30kw | temperature of inlet air:300-350℃ |

| ratio of raw material collection:bigger than 97% | type:50-1000 | Machine Type:Evaporator |

Description

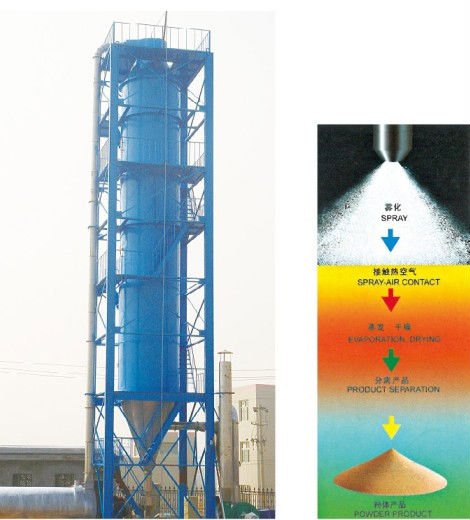

The liquid or paste raw material is sprayed into mini liquid drops by pressed atomizer which draws assistance from pressure or diaphragm pump, and quickly drying through heat exchange. (10-90 sec) at last, the powder or small granule is finished.

Features

1. Drying speed is fast and suitable for drying thermal sensitivity material particularly.

2. The finished product is ball granule with uniform size. Its fluidity and solubility are good. The purity of product is high and its quality is good.

3. It applied scope is wide. According to the characteristics of raw material, it can use hot air to dry and can also use cool air to granulate. It has strong adaptability to raw materials.

4. Its operation is simple and stable; its control is simple and convenient, easy to realize automatic operation.

Note:

1 The amount of evaporated water is related to characteristic of raw material and temperature of evaporation. The parameters in table is calculated as 150-160°C

2 Customer could choose different drying way such as: current steam, countercurrent steam and powder returning drying to meet the requirement of product.

3 The flow chart sketch is just for show, customer could pick subassembly according to need.

Applications

YPL Calcium chloride dryer is applicable in foodstuff, pharmaceutical, chemical industries, dyestuff, ceramics, biochemical, plastic industries and so on.

Technical Parameter

Note

1 The amount of evaporated water is related to characteristic of raw material and temperature of evaporation. The parameters in table is calculated as 150-160°C

2 Customer could choose different drying way such as: current steam, countercurrent steam and powder returning drying to meet the requirement of product.

3 The flow chart sketch is just for show, customer could pick subassembly according to need.

| Packaging Detail:wooden case |

| Delivery Detail:50 days after advance |