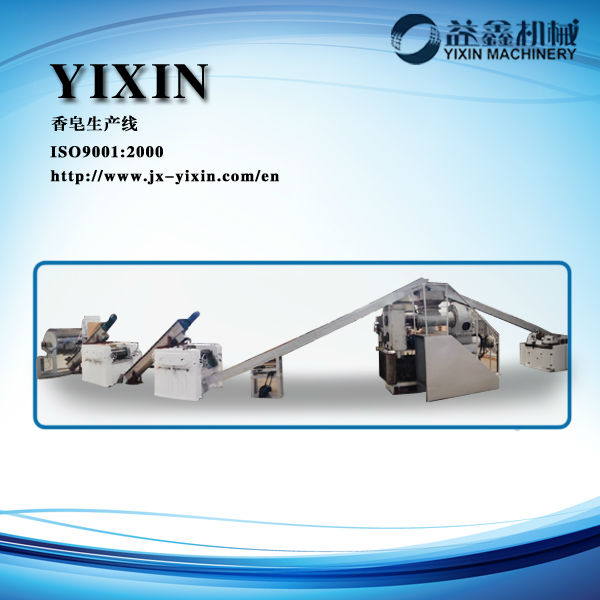

Yi Xin -- Soap Machine

| Product Type:Soap | Place of Origin:Jiangxi China (Mainland) | Brand Name:Yi Xin | Model Number:1200 soap line |

| After-sales Service Provided:Engineers available to service machinery overseas | Type:Hotel, household, travel soap production line | Automatic grade:Semi-automatic & Automatic | Drive type:Electric (alternating current) |

| Measurement:Refer to below specifications | Net weight:Refer to below specifications | Production capability:1200 kg per hour | Warranty:One year warranty |

Soap Machine

Yi Xin Machinery Co., Ltd

Toilet Laundry Soap machine line

Hotel, household, travel toilet soap machine production line

1) For 50 -1000g laundry soaps, 70-225g toilet soap production

2) Output:700kg-1200kg/hour.

3) Easy to operation and maintainance.

1)S125A Toilet Soap Stirring Mill / Soap mixer

1.Function

S125A Toilet Soap stirring Mill is used to stir the soap flakes in the process of producing toilet soap. Being simple structure and durable in life, the parts that are directly involved in the production are made of high quality stainless steel.

2.Main technical indexes

Stirring production capability (kg/time)--------------------------------- 70

Stirring spindle speed (rpm)--------------------------------------------- 36

Pneumatic System Pressure (mpa) ------------------------------ 0.4-0.8

Electric Machine Power (kw) ------------------------------------------- 5.5

Size (mm) ----------------------------------------------- 1980× 850 × 1400

2)S 405 Tri-roller grinder / Soap grinder

1. Function

S Series Tri-roller Grinder is designed to grind and mix the pellets of soap under normal temperature.

2. Main technical index

Model --------------------------------------------------------- S405

Diameter of rollers(mm)--------------------------------------405

Working length of rollers(mm)------------------------------810

Power of motor(mm)--------------------------------------------15

Speed ratio of rollers----------------------------------------1:3:9

Measurement(mm) ---------------------------1980x1848x1300

Weight (Kg) -------------------------------------------------- 5218

3) XT-1200 Soap Extruder / Duplex vacuum soap extruder

1.Function

XT-series Toilet Soap Strip Output Machine is specialized equipment which is used to produce semi-finished soap of plastic strip-shape after being grinded, extruded and exhausted. The semi-finished soap is to be cut into lumpish soap by toilet soap stamp machine.

2.Features

XT-series Toilet Soap Strip Machine is driven by the closed gears. The body of the machine being strongly welded, it is firm, efficient, artistic, less noisy and good quality. Parts of the machine which contact the soap materials in the production are made of high quality stainless steel.

3.Main technical index

Model number --------------------------------------------------- XT-1200

Production capability (Kg/h) --------------------------------- 670-1200

Outside diameter of screw rod(mm) ------------------------------- 300

Rotation speed of screw rod (rpm)--------------------- upper rod 12

--------------------------------------------------------------lower rod 10-16

Power of motor(Kw)---------------------------------------------- small 15

-----------------------------------------------------------------------large 22

---------------------------------------------------------(Various frequency)

Measurement(mm) ------------------------------------3818x1000x2288

Weight (Kg)------------------------------------------------------------5800

4) XDA-120 soap plodder / Soap printer

1.Function

XDA-120 Toilet Soap Stamping Machine is designed to solve the problems encountered in the usage of the XD-01 toilet soap stamping machine for the domestic soap manufacturers The machine characterized with lower vibration and noise, high efficiency and long service life. Together with strip output machines made in Yixin corporation, it satisfies technical requirements of cutting, slicing and stamping the toilet soaps.

2.Main technical indexes

Production Capacity (bars/min) ----------------------------------- 80-120

Soap size (g)---------------------------------------------------------- 50-180

power of motor (kw)--------------------------------------------------------- 3

Dimension (mm) ---------------------------------------- 3560×1410×1135

Weight (kg) -------------------------------------------------------------- 1750

5) Laundry Soap Rolling Cutting Machine (optional)

1.Function:

Soap rolling cutting machine is used to cut soaps into cakes and stamp patterns on the soap. It runs by the moving of soap bar from vacuum plodder. The front two mould wheels are used to stamp patterns on the soap, and the rear wheel is used to cut soap. The machine is easy to operate and repair.

The surface of mould wheels is plated chromium. The characters and the shape of soap is clear and neat. The size and pattern are designed according to customers’ requirements.

2.Main technical indexes

Soap size (L, W, H): ------------------------------ (3-40)x(1-10)x(1-3.5)cm

The length is not adjustable after the cutter is finished, while the soap’s weight can be changed by adjusting soap’s width and thickness;

Capacity: ----------------------------- the same speed of vacuum plodder

Mould: ---------------------------------------------------------------with one set

Dimension: --------------------------------------------------800×400×800mm

Weight: ----------------------------------------------------------------------50kg

6) Laundry Soap Electric Cutting Machine(optional)

1.Function

Soap electronic cutting machine is used to cut soaps into cakes and stamp patterns on the soap. Adopt Delta servo motor and converter, voltage stabilizer and precision purified AC voltage stabilizer, to protect motor and electrical components and to keep high accuracy.

The mould wheels run by the moving of soap bar from vacuum plodder. Because of the electronic tracking system, it can cut soap bars with any sizes and weight after setting the computer.

The characters and the shape of soap is clear and neat. The size and pattern are designed according to customers’ requirements.

2.Main technical indexes

1. Size and Weight: ----- Adjusted by customer’s requirements

2. Power: ------------------------------------------ 2Kw, 380V, 50Hz

3. Capacity: ---------------------------- In step of vacuum plodder

4. Mould: ------------------------------------------------- with one set

5. Dimension: --------------------------------- 1000×400×1200mm

6. Weight: ------------------------------------------------------ 100kg

7) Water Cooler for cooled toilet bath soap(optional)

Parameters 03ACL 05ACL 08ACL

Standard chilling capacity:---------------4333 Kcal/h-------------------- 6740 Kcal/h ---------------- 10206 Kcal/h

Standard chilling capacity:---------------3900 w-------------------------- 6825 w ----------------------- 9884 w

Compressor power :----------------------- 2.3 Kw -------------------------- 3.6 Kw ------------------------ 5.8 Kw

Pump power:--------------------------------0.37 Kw ------------------------- 0.55 Kw ---------------------- 0.55 Kw

Pump power :-------------------------------- 16mH2O ------------------------- 15mH2O --------------------- 17mH2O

Size :-----------------------------------------825X520X900 --------------- 1450X820X1060 ----------- 1500X1450X800

KT-350 Soap Packing Machine

1.Function & Features

1).Double transducer control, flexible bag length cutting, operator needn't to adjust the unloading working, saving time and saving films.

2). Human-machine operation, convenient and quick parameter setting.

3). Self diagnosis failure function, clear failure display

4). High sensitivity optical electric color mark tracking &digital input cut position which makes the sealing&cutting more accurate.

5). Separate PID control to temperature, suitable for various packing materials.

6). Stopping the machine in selected position, no sticking to the knife and no waste packing film.

7). Simple driving system, reliable working, convenient maintenance

8). All the controls are achieved by software, convenient for function adjusting and upgrading.

2. Technical specifications

| Type | Film width(mm) | Bag length(mm) | Bag width(mm) | Product high(mm) | Film roll diameter(mm) | Packaging rate(bag/min) | Power | Machine size(mm) | Machine weight(kg) |

| KT-350B packing machine | Max.350mm | 65-190,120-280 | 30-160 | Max.60 | Max.320 | 40-230 | 220V,50/60HZ,2.6KW | 4020X770X1450 | 650 |

Yi Xin building soap factories worldwide

Honours and awards

| Packaging Detail:Soap MachinePacked by plywood @***** |

| Delivery Detail:28 Days |