WXC30C lathe machine

| Condition:New | Type:lathe | CNC or Not:Normal | Automatic Grade:Semi-Automatic |

| Max. Swing Diameter:130:770 | Place of Origin:Shandong China (Mainland) | Brand Name:haige | Model Number:WXC30C |

| Voltage:380V | Power(W):65KW | Dimension(L*W*H):12.0mX2.2mX1.5m | Weight:6.0T |

| Certification:ISO9001 | After-sales Service Provided:Engineers available to service machinery overseas | Mschinery:Machine Tool Equipment |

semi-automatic hydraulic WXC40C bar peeling machine

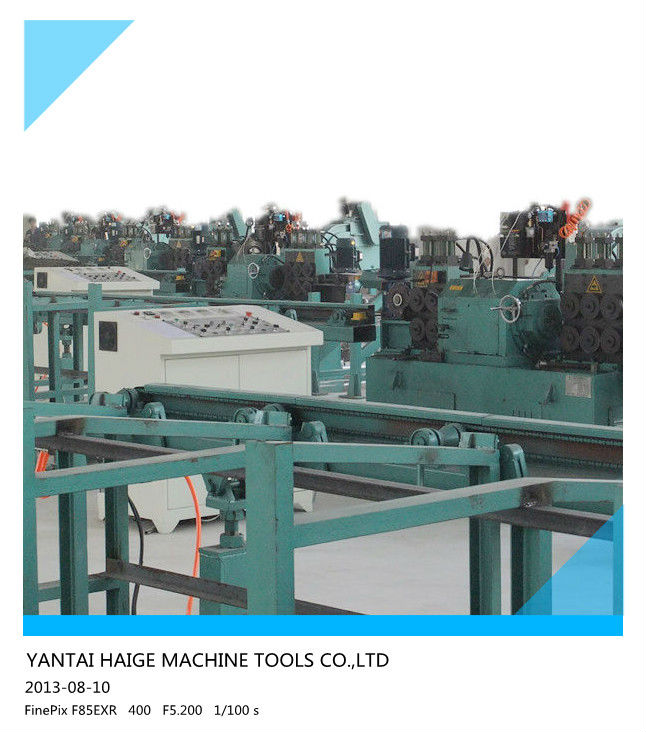

Yantai Haige Machine Tools Co., Ltd (original Yantai Ruihai Machinery Co., Ltd) establishes in 19999 and is a professional company engaged in producing finishing equipment and processing equipment of bright material, such as centerless lathe (commonly known as peeling machine or flaying machine), straightening machine, abrasive belt grinder (buffing machine), screw whirling mill and their auxiliary machines. It is an innovative and high technology enterprise, which integrates research and development, production and sale of finishing equipment for professional slender axles.

The company is equipped with specialized technical research and development department, and its ability of research and development, configuration of software and hardware and scale of personnel rank first in the industry. From design concept, technological level, production scale, quality in use to after-sale service, the company attains domestic leading level. It owns professional factories for machining and assembling, and full set of advanced equipment of precision machining, so it can produce high-precision core components by itself. Further more, the company possesses abundant ability of research and development, and perfect after-sale service system.

Diameters of products manufactured by the machine vary from Φ5mm to Φ350mm. The company can contract for full-set planning, design and manufacture of metal bar, tubing, and finishing line of wire rod, and meet the needs of customers at different levels. We are able to help users achieve digitization and automation control and management. We can also meet the needs of larger enterprises at home and abroad, and enterprises which require the equipments have higher degree of automation, to fundamentally enhance users’ production efficiency and product quality.

Main Technical Parameters

Specification | WXC40C | |

Raw Material | DiameterRange(mm) | Φ6~Φ42 |

| Raw Material Length (mm) | ≥1400 | |

| Tensile Strength (M pa) | ≤1100 | |

| Surface Hardness | ≤HB320 | |

| Curvature (mm/m) | ≤1.5 | |

| Diameter Tolerance | according to GB 702-88 second group | |

| Roundness(mm) | ≤50% of diameter tolerance | |

| Surface Roughness (Ra) | ≤25~50mm | |

Finished Goods | DiameterRange(mm) | Φ5.5~Φ40 |

| Unilateral Cutting Depth (mm) | 0.2~1.0 | |

| Diameter Tolerance | ≤IT9 (standard tolerance grade) | |

| Surface Roughness (Ra) | ≤6.3μm | |

| Roundness(mm) | ≤0.03 | |

Feeding Cutting Speed (m/min) | 1.0~8.0(for continuous chips and high strength and hardness should reduce the speed) | |

Cutter Head Rotational Speed(rpm) | 900-2500 | |

Main Machine Motor Power (KW) | 45 (2 Poles) | |

Auxiliary Machine Motor Power(KW) | 4 X 2(4 Poles) | |

Main Machine Outline Dimensions (Length*Width*Height) m | 2.0mX2.2mX1.5m (for your reference) | |

Full Set Machine Outline Dimensions (Including auxiliary machine) m | 12.0mX2.2mX1.5m (for your reference) | |

Main Machine Weight | 3.3(4.5) | |

Total Capacity(KW) | 65KW | |

Compressed Air Source(user prepare by themselves) | 0.5~0.8MPa,1.8m3/min,more than 0.8 m3 gasholder, two-stage oil-water separator and compressed air freezing drier | |

| Packaging Detail:seaworthy packing |

| Delivery Detail:1 year |