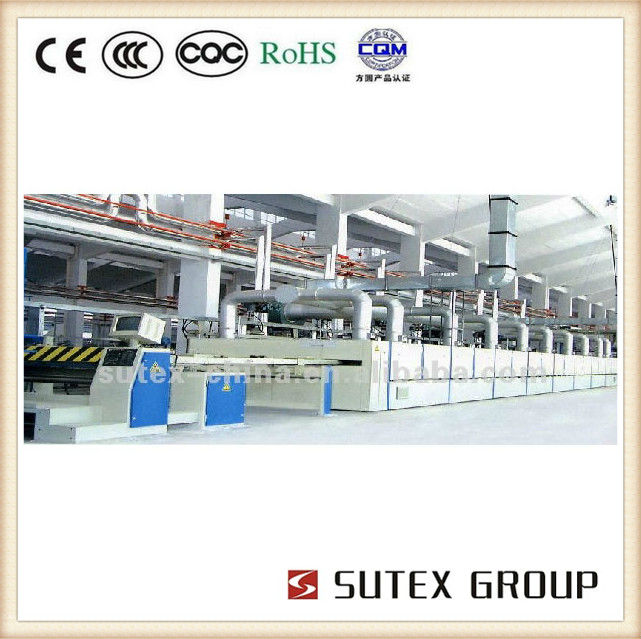

WP2000 OIL-FREE HEAT-SETTING STENTER

| Condition:New | Automatic Grade:Automatic | Place of Origin:Jiangsu China (Mainland) | Brand Name:SUTEX |

| Model Number:WP series | Voltage:380V | Power(W):11Kw | Certification:CCC,CE |

| Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | machine width:2600mm | working width:2400mm |

| fabrics type:knitted fabrics | mechanical speed:100m/min | heating source:thermal oil,gas or electricity | Fabric held by:pin |

| Uncurler:4 finger uncurler | Number of chambers:6 | Electric control:by inverter and PLC |

DESCRIPTION:

It applies to the stentering and setting of both woven and knitted fabrics in the open width.

The stenter is oil free type and adopts twin air ccirculation system to achieve good heat setting effect.

Heating source: Thermal oil, gas or electricity.

STRUCTURE:

1.Fabric entrance scafford with wen width limiting device:scolling the entrance fabrics and calibrations,alternatively for high or low level fabric entrance.

2.Centering device(cloth guider):It contains both functions of guiding and straight calibration.

3.Paddle mangle:squeezing and resining

4.Speed compensator:the tension between paddle and stenter can be controlled.

5.Manual skew weft straightner:fabrics skew and bow web can be controlled.

6.Entrance control bridge:assembling all electrical control parts in central bridge,it covers 95% control function.

7.TV monitor:with CCD camera at the exit section,it can monitoring the status of fabrics delivery and ensuring the quality.

8.Entrance box and overfeeding,pining on device.

9.Selvedge unculer and position drive device:To scroll the fabric selvedges and tracing up the selvedge.

10.Pin,clip chain rails,rails rack:Using pin plate or clip plate to transport fabrics to the heating chamber.

11.Heatingchamber

12.Web width adjusting device:To adjust the fabrics width.

13.Exhaust ducts:equipped with exhausting fan monitor.ait duct .inlet and outlet air damper.

14.Air cooling zone and water cooling cylinders:optional for air cooling or water cooling cylinders.

15.Selvedge cutting device and centering cutter:remove the fabrics selvedge and suction tube.

16.Fabrics delivery arrangement,plaitor and batching device:with exit plaiting down and winding up devices.

3.PROCESS FLOW

Feeding frameàcentering deviceà2-bowl padderàlower overfeedingàmechanical weft straightening rolleràscrew expanding rolleràupper overfeedingàInfrared selvedge sensing deviceà4 finger uncurleràpinning onà6 drying chambersàair coolingàdepinningàplaiter

4.TECHNICAL SPECIFICATIONS

1) Machine width: 2600mm

2) Working width: 2400mm

3) Fabric type: knitted fabrics

4) Mechanical speed: up to 100 m/min

5) Heating source: thermal oil (oil boiler to be prepared by buyer)

6) Fabric held by: pin

7) Uncurler: 4 finger uncurler

8) Number of chambers: 6

9) Electric control: by inverter and PLC

5.DETAILES:

Certificate of our Company:

ISO9001-2000

ISO14001:2004

OHSAS 18001:1999

| Packaging Detail:seaworthy export packing |

| Delivery Detail:Within 65 days after receipt of T/T in advance and L/C at sight |