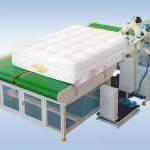

Worktable move CT-481 cnc router china price

1.9KW Italy HSD spindle, 2.24000rpm/min, 3.8 tools capacity of alloy cutter plate, 4.Taiwan Syntec control system - details see: https://www.machineto.com/worktable-move-ct-481-cnc-router-china-price-10343472

| Condition:New | Place of Origin:Guangdong China (Mainland) | Brand Name:TUP | Model Number:R-1325ATC8-OP |

| After-sales Service Provided:Overseas third-party support available | Spindle:9kw Italy Air-cooling | Feed Speed:60m/min | Vacuum Pump Power:5.5kw,7.5kw(optional) |

| Processing Precision:+-0.05mm | Working Mode:Worktable move | Electric elements:Schneider | Operating System:Weihong NK260 |

| Taper automatic system:8 tools | Moter System:Servo-YASKAWA | Software:UG,MASTERCAM Artcam,etc. |

CNC router center(R-1325ATC8-OP)

Applications; Plate-typed furniture, arts & crafts items, cabinet door, sound box, 3D musical instrument, moulds and items which have basic requirements of AUTOMATIC.

Features;

| 1 | Working area: | 1300 X 2500 X 200mm; |

| 2 | Working Mode | Worktable move; |

| 3 | Casting steel | Body with aging & tempering treatment; |

| 4 | Vacuum worktable | 4 areas*(32holes)equipped with 7.5kw water pump; |

| 5 | Spindle | 9kw Italy HSD air-cooling spindle,0-24000rpm/min(Italy); |

| 6 | Stepper and Driver | Yaskawa Servo Motor and Driver(Japan); |

| 7 | Linear guide rail and Slider | Hiwin 25mm slider and 25mm linear guide rail(Taiwan); |

| 8 | Inverter | Delta 9kw(Taiwan); |

| 9 | Electrical Component Breaker | Germany Schnelder; |

| 10 | Electrical Component Cable | Germany HELUKABEL; |

| 11 | Reduction Box | Taiwan; |

| 12 | Drag chain | Tatally closed drag chain,can be bended as 150°; |

| 13 | Rack gear&pinion | Transmission for X and Y Axis; |

| 14 | Ball screw | Taiwan TBI ball screw transmission for Z axis; |

| 15 | Approaching sensor switch | Dustproof, waterproof & antiseptic (3 pcs for X,Y and Z axis); |

| 16 | Heat Dissipation | Fan Cooling; |

| 17 | Control System | High version Weihong servo control system,All in one cabinet; |

| 18 | Tool Changing | 8 tools changer automatically,ATC device; |

| 19 | Dust collector | 2.2KW monocular dust collector(double bag); |

| 20 | Working command | G code,.NC,HPGL; |

| 21 | Software available | Artcam,Alphacam,Mastercam,Type 3,UG,Caxa,JD Paint etc; |

| 22 | Collect | 8 PCS; |

| 23 | Working voltage | Three-phase380V/or 220V/50-60HZ; |

| 24 | Gross weight | 4000KG; |

| 25 | Packing size | 2300*3400*2300mm; |

Sample

Specifications

No. | Description | Parameters | |

1 | Working areas | X working area | 1220MM |

| Y working area | 2440MM | ||

| Z working area | 200MM | ||

2. | Machine’s accuracy | Processing accuracy | ±0.05MM |

| Re-orientate accuracy | ±0.02MM | ||

3. | Machine construction | Table | Vacuum worktable |

| X,Y,Z | X, Y axis: Pinion & gear transmission, Z axis: Ball screw transmission; | ||

4. | Speed | Max. speed | 60M/MIN |

| Max. cutting speed | 30M/MIN | ||

5. | Spindle motor | Rate | Italy HSD Air-cooling 9KW |

| Rotary speed | 6000-24000R/MIN | ||

| 6. | Working voltage | AC380V/50HZ | |

| 7. | Control system | Taiwan Syntec Control System | |

| 8. | Control command | G-code, *.NC | |

| Packaging Detail:Standard Package:Foam inside ,poly film outside,wooden pallet is optional. |

| Delivery Detail:20Days after receipt of down payment |