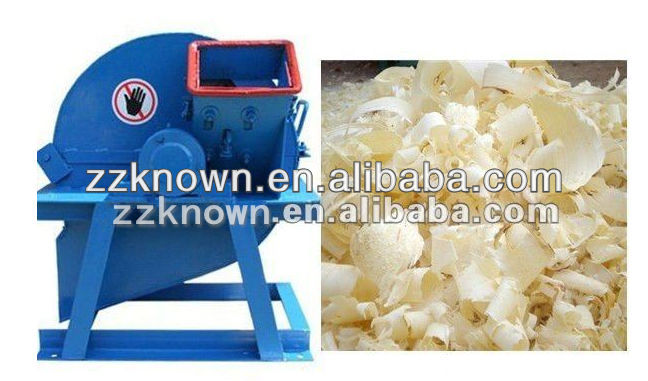

Woodworking machinery wood shaving machine for animal bedding

| Condition:New | Application:wood shavings | Production Capacity:1000 KG/h | Place of Origin:HEN,Henan ,China China (Mainland) |

| Brand Name:Known | Model Number:KN-800 | Voltage:220 V | Power(W):30 KW |

| Dimension(L*W*H):1850*800*1100 mm | Name:Wood shaving machine | color:various | Size:can make according to your request |

| Use:wood shavings | Feature:High efficiency and easy opreation | Power:Diesel engine | Management Certification:ISO 9001:2008 |

Woodworking machinery wood shaving machine for animal bedding

Introduction wood shaving machine::

Wood shaving machine is mainly used to batch production thickness uniform wafer shavings, is a kind of automatic wood shaving machine. It includes frame, in the frame of platform, fixed on the platform of the frame, wood by feed port into the machine, inside the machine after slice blade with shavings, out of the wood chips size, thickness, and wood factory hand out shavings no difference.

Scope of application :

can do particle board (plywood),is the paper mills do wood pulp paper raw materials, transportation company do fragile transport fillings, used for small pigs, cattle, sheep and all kinds of animals in the nest do fillings, can also be used as a biological energy.

This machine can will logs, branches (branch), plate edge processing into shavings, production out of the wood chips and furniture factory production out of the wood chips, automatic feed equipment, greatly improving the production speed, but also save the time and manpower.

The machine is a automatic grinding processing wood into shavings equipment, raw material by feed port into, the first the blade, cutting into the crushing chamber, by high speed rotating hammer of impact and shear knife under the appointment of crushing, again by the built-in wind leaf produce wind the screen to send discharging mouth or external fan pumping discharge port. Shaving size by adjusting blade length and mesh aperture size to decide to meet the various needs.

Wood shavings equipment used mainly by the usualmaintenance:------------

(1) after use every day to adjust the belt elastic, drop 6-10 mm appropriate.

(2) cleaning machine internal, not left last crushing material.

(3) bearing timely charging butter, continuous work 3-4 hours filling a butter, should pay attention to observe.

wood shaving machine Technical parameters :

| Model | KN-420 | KN-600 | KN-800 |

| Cutter diameter | 420 mm | 610 mm | 750 mm |

| Blade number | 4 pieces | 4 pieces | 8 pieces |

| Blade size | 90*60*8 mm | 150*70*8 mm | 150*100*10 mm |

| Import size | 140*100 mm | 190*150 mm | 240*220 mm |

| Spindle speed | 700 r/min | 600 r/min | 560 r/min |

| Match power | 7.5 KW | 15 KW | 30 KW |

| Production | 300 kg/h | 500 kg/h | 1000 kg/h |

| Machine size | 1200*500*700 mm | 1550*630*950 mm | 1850*800*1100 mm |

detailed information :

| Delivery time | After receive deposit,we need 15 days to make the goods |

| Payment | We do payment in L/C, L/C at sight,T/T or paypal |

| Supply ability | 100 sets /month |

| Sample | 7-10 days ,also according to your quantity |

| MOQ | Usually we don’t have strict demands on it; we welcome all kinds of order. |

| Packing details | 1 piece /carton |

Use of fault and the solving methods:--------------------------------

(1) wood shavings mill when using belt easily crush zone, the reason is motor rotor and timber mill rotor different heart, but left, right mobile motor position, or in the motor base feet surface and pad, adjusts the two rotor concentricity.

(2) wood shavings mill production is low. Reason: blade not sharp or knife not to adjust to the right position. Means of settlement: will unload knife, the knife tablet, adjust the blade to the appropriate chip position.

(3) feed difficulties, knife chip sweaty. Reason: tool wear is serious, the fixed knife gap too big or too small. Means of settlement: repair knife piece, ensure blade sharp. Adjust the fixed knife gap 2-3 mm, blade Angle is not greater than 30 °.

(4) feed fast machine system halted. Reason: feed speed not divide evenly, blade is not sharp. Means of settlement: uniform feed, guarantee the crushing bin not in stock. Repair knife piece, make knife chip speed.

(5) bearing fever. Reason: in bearing no butter, bearing not installed flat, bearing damage. Belt installation too close. Means of settlement: bearing inner and butter, bearing school balance, change new bearing, adjust the belt elastic, enables the equipment to work normally .

Company Introduction

Our products have been exported to Europe, America, Southeast Asia and other countries and regions. OEM service is also available.

We can also produce goods according to customers' demands of different types. We strive to make our products in efficient and cost effective ways by outstanding technology and excellent service. We heartily hope to create a brilliant future with our worldwide friends.

| Packaging Detail:1piece / cartonStandard export wooden case or According to the requirements of our customers |

| Delivery Detail:Within 15 days |