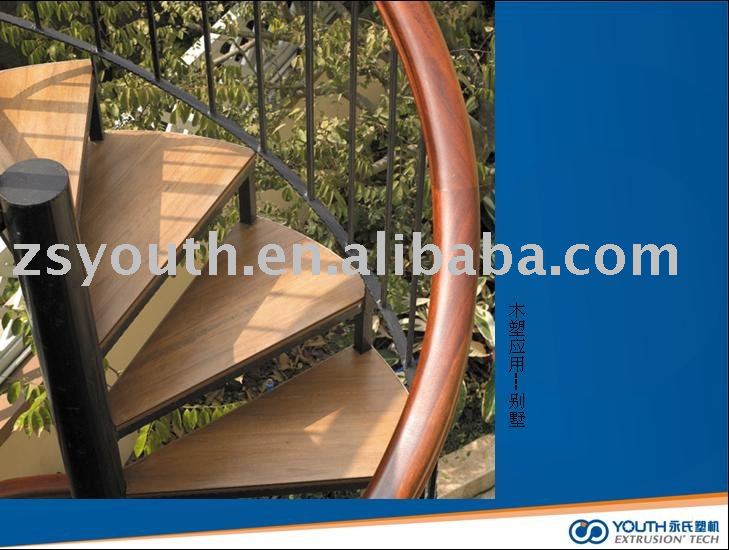

Wood Plastic Composite Production Line

| Place of Origin:Guangdong China (Mainland) | Brand Name:YOUTH | Model Number:SJ |

Wood Plastic Composite Production Line

Extruder

Youth’s single screw extruder of polyolefin pipe production line is specialized designed for polyolefin products. The design of screws can provide high-speed cutting and mixture for polyolefin material during the process. The special cooling way can prevent the obstruction of material caused by the transportation of heat. Special cooling accessory is installed in ‘reduced speed’ box to lower the high temperature caused by high-speed teeth of screws. Then the good quality and high capacity can be obtained.

Polyolefin moulding

Youth has accumulated 20 years experience on Pipe moulding. From design, production to testing, Youth owns a team of good technicians, have developed new-created 2-in-1 pipe and 4-in-1 pipe moulding. It can speed up the development of polyolefin production.

n Design of flow channel can avoid the dead spots and stagnation zones

n Spiral channel increase the heating area of material, lower the melting temperature

n Large-volume flow channel have equality pressure of melting, decrease the pressure loss.

n Mandrel design with rigid construction, avoid floating.

n Easy assembly / disassembly

Vacuum Calibrator

Youth’s vacuum calibrator is made by stainless steel plates. The metal pips (inside and outside) use stainless steel pipes. With plastic adjustable sprayer and various internal pipes for adjusting the direction, the vacuum pressure inside can control the temperature and level of water, which can be controlled by setting system too.

Spray Cooling Bath

Youth spray cooling bath is made in stainless steel material. Transparent soft PVC films are installed on both sides, can be pull up for easy control. Six rows of sprayers are inside and guarantee the surface of pipes having enough cooling. Internal water temperature control system provides suitable water temperature. Two-channels can keep normal production during the clean up of channel.

Haul-off Units

The haul-off units designed by Youth for polyolefin pipes have different clipping power referring to different pipe sizes. The haul-off units can be designed in double-belts, triple-belts, four-belts, six-belts, etc. The belts have independent moving system and the clipping power is controlled by air pressure. Belts are following the direction of nylon slides. Stable with less vibration. Made in good materials and can be durable.

Cutting Devices

Youth offers planetary saws for polyolefin pipes cutting. The saws are made in platinum steel. Different clipping system is used for different sizes of pipes to guarantee the stability of pipe cutting. We use Siemens PLC control system to provide an accurate cutting.

Co-Extrusion

It is very common to use co-extrusion in the polyolefin pipes production. We can provide two layers or many layers of co-extrusion pipes. The co-extruder can be connected with the main extruder or independent.

| Packaging Detail:Packaging standards and packaging recycling: wooden box, no recycling. |

| Delivery Detail:About 30days after the deposit |