Wood Machinery MF-360A Model Edge Machine Edgebanding Wtih CE Certification

| Condition:New | Place of Origin:Shandong China (Mainland) | Brand Name:Yongwang | Model Number:MF-360A |

| Voltage:220V/380V | Power(W):7.1KW | Dimension(L*W*H):3800/820/1450mm | Weight:1800kg |

| Certification:CE/ISO etc | Warranty:12 Months | Model:MF-360A | Total Power:7.1kw |

| Thickness Of Seal Sideband:0.4-3mm | Width Of Seal Sideband:12-45mm | Transporting Speed:8-18m/min | Overall dimensions:3600/1000/1400mm |

| Net weight:1800kg |

Main Technical Parameter

| Model | MF-360A |

| The Thickness of Seal Sideband | 0.4-3mm |

| The Width Of Seal Sideband | 12-45mm |

| The Transporting Speed | 8-18m/min |

| Transport Motor | 1.5kw |

| Glue Post Motor | 0.55kw |

| On A Leaver With An Motor From Beginning To End | 0.37kw*2*(12000Rpm/Min) |

| Precisely Repairing Motor From Head To Foot | 0.75kw*2*(18000Rpm/Min) |

| Polishing Motor | 0.18kw*2*(18000Rpm/Min) |

| Glue Box Heater | 1.5kw |

| Air Pressures To Side | 0.7Mpa |

| Total Power | 7.1kw |

| Size Of Appearance | 3600/1000/1400mm |

| Weight | 1800kg |

Configuration Form:

| Model | MF-360A |

| Gluing/Cutting/Clamp | √ |

| End-Trimming Device | √ |

| Fine-Trimming Device | √ |

| Scraping Device | √ |

| Polishing Device | √ |

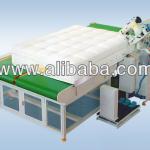

Picture Banding Machine:

Picture Factory:

1), Gluing/Cutting/Clamp

The glue mechanism asopt a special structure to gelatinize the plates and coating materials uniformly,ensure a more solid conglutination.

2),Edging Cutting

End-trimming mechanism through a precise guide track movement,adopt automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

3)Fine Trimming

The fine trimming machanism used for repairing the excess edge materails,adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

4),Scraping

The scraping unit for a perfect finishing of the applied edge.

5),Polishing

The polishing device adopt the board processed by cotton polishing wheel,by end polishning to the make a more smooth surface.

Picture Factory:

Summarize:

Adopt to the sealing of pvc,wood plank and veneer etc.

1), Using imported quality engine and electric components.

2), Serialized products,a wide range of selection by customers.

3), High precision and effciency.

Auxiliary Machine:

Dust Collector

Main Information

| Qingdao Yongwang Woodworking Machinery Co.,Ltd | |

1), HF MOTOR IS COMPLETELY MADE IN ITALY (Except for the economy E) 2), applicance component are completely supplied by SIEMENS,SCHNEIDER,OMRON,DELTA,LG 3), pneumatic component are completely supplied by AIRTAC in Taiwan 4), broadswaard and knife eliminate the limitation of material 5), five roller system make it more fasteness and steadily 6), reliable performance of 19m/min speed of feeding , can 9-19 stepless speed regulation (Economy E is a two-speed) 7), min wedth of sheet is 60mm 8), the max thickness of real wood sealing can up to 15mm while min is 0.4mm 9), The humane folder system, operating in the Edge of thickness change easier | |

| Packaging Detail:Plywood Case |

| Delivery Detail:have in stock |