wheat flour milling machinery

| Condition:New | Place of Origin:Hebei China (Mainland) | Brand Name:Goldrain | Model Number:6FTFS-100 |

| Production Capacity:75%-85% | Voltage:can supply 440v 50hz, 380v, 50hz and 440v,60hz,380V/50HZ | Power(W):336kw | Weight:85t |

| Dimension(L*W*H):48000*10000*12000mm | Certification:ISO9001 | Warranty:ten years | After-sales Service Provided:Engineers available to service machinery overseas |

| Type:Grain Processing Equipment | Processing Types:wheat ,maize, corn | Capacity:5T-1000T | Design:anvance technology and Drawing support |

| Quality:ISO9001 | after-sale service:long life | Production Capacity::70-85% super fine flour | Installation type:cement building |

| Installation time:45-60 days |

Product information:

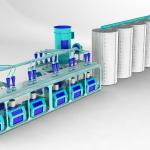

Our wheat flour mill includes cleaning, milling and packing.

Technical for cleaning system:

Three sieves,two beating,two removing stone, three magnetic selecting ,one moisture temper.

Technical for flour system:

Ten Milling,three Six-bin square sifter, two Purifier make up of 4B,6M,1S,1Tand 2Bran finishers.

The parameter for 100T/D wheat flour milling machinery

1. Total length of the roller: 12000mm

2. Production capacity: 100/24H.

3. Flour quality: obey the People's Republic of China's GB1355-88 standard

| Volume weight/g/L | Faultiness grain content/% | Impurity content /% | Mineral content/% | Moisture content/% | Odor content/% |

| ≥750 | ≤6.0 | ≤1.0 | ≤0.5 | ≤13.5 | natural |

Ash:to produce grade 2 flour: 0.80%(dry weight) to produce grade 1 flour: 0.65%(dry weight)

Flour extraction: To produce standard flour: 75-82%

To produce grade 2flour: 72-75%

To produce grade 1flour: 70-72%

4. Power supply: About 336kW.

5. Used under: Voltage: 380V, Frequency: 50HZ, below an altitude of 1000m.

6. Total weight of the equipment: about 85T.

7. Workshop style and dimension: 48000×10000×12000mm(Tripod structure).

A.The clean part:

Includes beating, screening, destoner, magnetic separator and dampening. Different capacity machine line has different number of beat, screen and stoner.

To ensure the flour Quality and the working life of the mill by removing the impurities in the wheat before go to mill,

Beat: Through the beat function of the wheat scourer, brusher to remove dust sand small seed, bacterial count and insect seed.

Screening: To remove large and small impurities in the wheat seed by make the wheat go through vibrating sieve and aspiration sieve.

Destoner: Mainly remove stone in the wheat to protect them milled into the flour and also protect the roller on the milling process.

Magnetic separator: Remove metal material in the wheat to keep the roller safe and also avoid flour exploration accident of spark caused by the impact of the metal impurities and the machine.

Dampening: Dampening the wheat bran before mill to ensure the bran's integrity during the milling processing, avoid the bran going into the flour to keep flour quality.

B.The flour milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: Mill the wheat to break the integrity by the roller moving

(2) Sifter: To separate the flour and bran, also separate large size and small size to enssure flour quality.

C. Packing part.

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

If you are interested in our products,please contact us freely:

| Packaging Detail:all the machines are nude packaging, they are loaded by container |

| Delivery Detail:after 35-40 days when we receive your deposit |