wfi distiller

| Place of Origin:Shanghai China (Mainland) | Brand Name:SHPM | Model Number:LD | Application:Liquid |

| Type:distillation | After-sales Service Provided:Engineers available to service machinery overseas | application for:food and drug industies |

Introduction:

| LD multiple effect distiller is designed and produced according to standard of <<YY0229 multiple effect distiller water machine>>, all parts are made of 304 or 316L SS, The produced distilled water is in high purity and pyrogen-free. Distilled water produced by Multi-effect distillation unit comply with requirements of U.S. , EU and China pharmacopoeia for WFI . It is a perfect device for pharmacy manufacture to produce diversified blood goods, injection, infusion, biologic antibiotic and so on. Working principle: Feed water is heating by plant steam in I effect pre-heater , then enters into posterior each effect pre-heater , pre-heated by plant steam condensate ,steam and distilled water are heating for them in the condensers ;In the top of evaporator , after water separator , enters evaporation tube uniformly distributed , becomes film type stream in the evaporation tube ; Because very thin, so after evaporation , can become rebirth steam very quickly , the feed water which are un-evaporated transport to the next effect , as the feed water , this process repeats on and on until the feed water in last effect are un-evaporated , drain as condensate ; The rebirth steam (evaporated feed water ), ascends in the evaporator spirally , enters pure steam pipeline as next effect pyrogen gets through middle and top special separator ; In the evaporator , pyrogen of rebirth steam absorbed by feed water condenses distilled water ; the processes for each effect are same , distilled water of each effect and rebirth steam of last effect are collected by condenser , heating change with cooling water and feed water , after cooling , become distilled water ; On-line detection for conductivity , qualified distilled water as WFI output , unqualified drain . |

| After three times separation , feed water turns into rebirth steam which are clean .The first time evaporation , feed water enters evaporator , then flow , at the same time evaporates ,The evaporated feed water in the lower extreme of evaporator back turns , in the action of gravity , foreign matters separate in the under-part , this is the second separation time ; For the third time , the rebirth steam (evaporated feed water ) ascends in the evaporator spirally , separates in the middle and top special separator . |

| The cooling water only gets through condenser, can drop temperature for distilled water produced by each effect and rebirth steam .Plant steam is heating for feed water in I effect evaporator and pre-heater, becomes condensate after absorbing pyrogen, then drain out of machine. Partly of air in feeding water cannot condensed, called incondensable air , according to the machine type , they can exhaust by device in the top of evaporator. |

Technical parameters:

| Model | Output (L/h) | Steam consumption (Kg/h) | Purified water consumption (Kg/h) | Cooling water consumption (Kg/h) | Dimension (mm) | Weight (Kg) |

| LD100-3 | 100 | 50 | 180 | 170 | 1000*800*2000 | 240 |

| LD200-3 | 200 | 75 | 240 | 240 | 1000*800*2000 | 240 |

| LD300-4 | 300 | 90 | 360 | 230 | 1100*800*2200 | 450 |

| LD500-5 | 500 | 130 | 600 | 160 | 1600*900*2500 | 920 |

| LD750-5 | 750 | 190 | 840 | 195 | 1700*1000*2900 | 1100 |

| LD1000-5 | 1000 | 260 | 1100 | 270 | 2100*1100*3100 | 1800 |

| LD1500-5 | 1500 | 400 | 1670 | 420 | 2500*1300*3400 | 2100 |

| LD2000-5 | 2000 | 525 | 2200 | 550 | 3000*1300*3400 | 2200 |

| LD3000-5 | 3000 | 800 | 3300 | 880 | 3500*1500*3800 | 3300 |

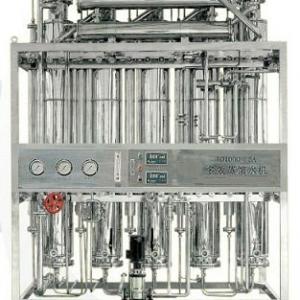

Equipment picture:

| Packaging Detail:wooden box |

| Delivery Detail:50-70days |