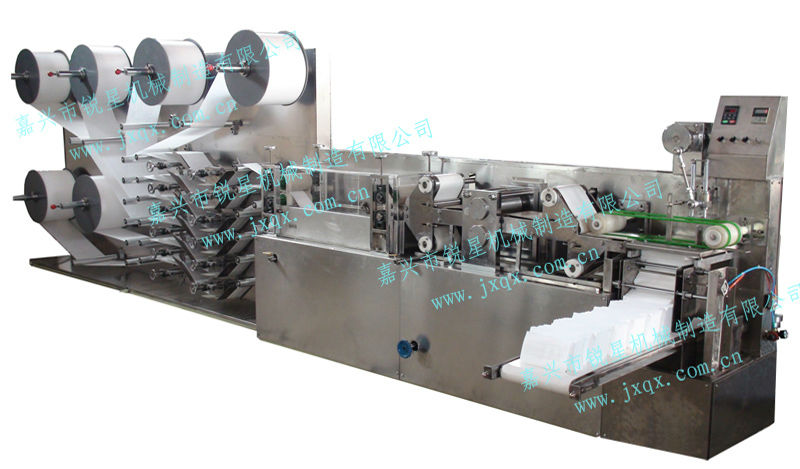

wet wipes double Z-fold machine

1.PLC control., 2.Automatic corrrection system., 3.Cost-effective, 4.Easy maintaining and stable running. - details see: https://www.machineto.com/wet-wipes-double-z-fold-machine-10326465

| Condition:New | Place of Origin:Zhejiang China (Mainland) | Brand Name:Qixing wet wipe machine | Model Number:QX-6F |

| Voltage:380V | Power(W):2kW | Dimension(L*W*H):1500mm*550mm*1500mm | Weight:600kg,850kg |

| Certification:wet wipes machine | Warranty:wet wipes machine | After-sales Service Provided:Engineers available to service machinery overseas | Producing speed:100-180bag/min |

| Volts:220V | Frequency:50Hz | Total power:4.35KW | Size of wet tissue:L:80-220mm,W:70-200mm |

| Size of bag:L:45-150mm,W:50-100mm | Dimension:L:1600mm*W:1000mm*H:2000mm | Function:folding,wetting,cutting,counting,stacking | wet wipes machine:Cost-effective |

Wet wipes making machine can make wet wipes ,baby wet wipes, industry wipes,etc.

Wet wipes can be folded many ways and the wet wipes looks fine.

The packaging of wet wipes can be equiped with.

Wet wipes can be made ofspunlace nonwoven fabric, hot air cloth, rolled cloth, acupuncture cloth.

The wet wipes making machine is easy to control.

Product Description:

Exclusive domestic research and development, the device per minute production in 2000-2500, compared to the production of more efficient than the first generation QX-5F, better use the recommended models, has been successfully applied for the patent, without thethe company allowed the use of the company's picture and video promotion, the company will pursue its legal responsibility.

- Processability of raw material: spunlace nonwoven fabric, hot air cloth, rolled cloth, acupuncture cloth.

- Machine with plant design multifunction the profiled folding system, folding N, C, Double Z and other specifications can be adjusted within a certain range, and gear CVT control the length of the product.

- The machine is equipped with 6 foot raw material feeding system, starting with the raw materials traction - automatic folding - automatic liquid - automatically roll off - automatic stacking - about dislocation count - automatically output products, the whole line is fully automatic complete.

- Dimensional accuracy of the machine with 6 tension controller to adjust the tension of the finished product to guarantee folding.

- The machine is equipped with a complete set of automatic liquid automatically roll off the cutting device and product output system.

- Machine the entire delivery system used in all imported conveyor transport, solid, durable, non-polluting.

- The machine adopts imported converter control operation, was equipped with a PLC program and a color touch screen, cabling specifications, simple, safe and easy to operate.

- Machines involved in product parts are made of stainless steel, bearing domestic quality 45 # steel material, the use of high-quality bearings.

- Machine rack adopt international channel welded surface for anti-rust paint treatment, the exact size of the welded frame the bracket appropriate reinforcement, pulleys, gears and transmission parts,center poison accurate to ensure smooth operation of the machine.

- Standard parts used in all domestic quality 45 # steel screws and Allen screws, stainless steel screws impact on the finished product easy.Machine all plating finish, anti-rust properties.The device was equipped with PLC programming procedures, the servo electrical, color touch screen control joint production, complete automatic stacking and output products cropped, greatly improve work efficiency.

| wet wipes machine model | QX-6F |

| wet wipes making machine producing speed | 2000-2500pcs/min |

| wet wipes machine rated voltage | 380V |

| wet wipes machine rated frequency | 50Hz |

| wet wipes machine dimension(L*W*H) | 7800*1200*2000 |

| wet wipes machine weight | about 3500kg |

| Packaging Detail:Packaging in wooden case |

| Delivery Detail:45 Days |