waste plastic recycling 6M-PP Melt Blown Cartridge Making Production Line

| Condition:New | Type:Other | Medium Material:PP | Place of Origin:Jiangsu China (Mainland) |

| Brand Name:AJMS | Model Number:AJMS-RPJ-6M | Voltage:380V/220V | Power(W):150KW |

| Dimension(L*W*H):8000mm*4000mm*3000mm | Weight:5T |

PP Melt Blown Filter Cartridge Machine

Main features of pp melt blown filter cartridge machine

&Good quality

Each part produced by famous company(inverter is HOLIP DANFOSS,senor,solid state reply and other electric machine

is DANFOSS.)

&Electric-saving

1. A leading manufacturer,producing the machine for more than 20 years.

2. Advanced technology,saving electric(power is about 90kw)

&Large production capacity

1. 5800-6000pcs/24hours.

&Easy operation

1. Our engineers will teach you unit you can operate by yourself.

2. Automatic feed machine and automatic cutting machine.

Samples

The parameter of the production line ( best energy-saving )

| Rated power: | 150KW(without molds cleaning oven) |

| actual power | 90KW |

| Raw material | Polypropylene(Fiber Grade) |

| Internal diameter(Default) | 28mm(15mm-40mm is for customer’s request) |

| Outer diameter(Default) | 38mm-120mm( on the basis of OD 28mm.) |

| length | 10’’,20’’,30’’,40’’.............100’’ |

| Filter precision | 1um,5um,10um,20um,30um...............100um |

| Surface of filter cartridge | Smooth surface orange peel surface Grooves surface(grooving machine ) Dotted surface (extra tool ) Graining toll/stripe surface (extra tool) Logo on surface (carving machine produce logo & com pany name on the surface of pp filter) |

| Machine weight | 5Tons |

| Wastage of material | material wastage will be needed for starting machine |

Layout of the whole product line(6.5m*7.5m): 50m2 is good,100m2 is better.

The details about this machine

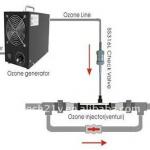

(In fact, it has these parts: Rotary blower, Spinning system, Air Heating machin

e, Extruder,mould System, work table, Auto receiving system, electric control

sysem,Molds cleaning oven, )

(This picture is for reference only)

Payment :T/T ,30% deposit and balance before shipment .

Delivery time: 45-55 days at most upon receipt of deposit.

Packing: Each packed in plywood case.

Voltage: AC380V 50HZ(or60HZ) DC220V,

40 feet container could contain 1 set of pp melt blown filter cartridge production

line.

Training:

There is two methods.

First one: 5-10 days Our engineers training in your factory, air tickets (go and back)

& accommodation,that mean all costs by your company.

Second one: we could free train your delegates (1~2person) for 2-3 days.

After-sales service:

We will provide one-year service for free. We provide the new main parts (frequency

changer, screw rod, extruder barrel, electromotor, gear box) if yours is broken for

free without human factor. PLS, operate our machine correctly.

If you want to know more about 2E&2M pp melt blown filter cartridge machine

or be interested in other productions(we havepp filter cartridge machine, 1E&3M,

1E&6M,1E&1M,2E&2M pp melt blown filter cartridge machine, ), Please contact me.

My skype iseason_jingand my telephone number is+86 15152255563. Of course,

If you are available, welcome to our factory to visit.

2013 AQUATECH CHINA

Date:2013.6.5-2013.6.7

Location:The Shanghai world expo exhibitio

| Packaging Detail:Wooden Packing |

| Delivery Detail:30-60 days |