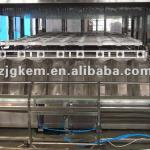

Washer filler capper three in one unit

| Processing:Washer,Filling Machine | Place of Origin:Jiangsu China (Mainland) | Brand Name:Chenxing | Model Number:CGF14125 |

| Voltage:380v | Power(W):35kw | Weight:28000kgs | Processing Types:Water |

| Certification:ce | Warranty:2years | After-sales Service Provided:Engineers available to service machinery overseas | Model:CGF14125 |

| Number of washing, filling, capping:14-12-4 | Capacity:3000-4000 | Suitable bottle size (mm):50-108 H=170-340 330ml-2.25L | Pressure (kg/cm2):2~3 |

| Power (kw):Total motor4.5kw | Overall size (mm):2100*1400*2500 | Weight(kg):2500 | brand:Chenxing |

| name:Washer, filler, capper three-in-one unit |

Washer, filler, capper three-in-one unit

Product introduction:

1.This machine has washer, filler, and capper three functions in one body;

2.it is automatic in total process, suitable for PET bottled mineral water, pure water and many other no gas containing drinks.

3. It makes by high quality SUS304, key parts are precision machined by NC tool.

4. The total machine uses advanced photoelectric detection technology to detect each parts operation status, no bottle no

filling, and no bottle no capping, automatic and easy operation.

Main features of the equipments

1. Using the wind sent access, with clamp hanging the bottle neck; which can keep the bottle shape and high-speed.

2. Bottles transmission adopts clip bottleneck technology, clean and fast.

3. Filling uses liquid cylinder feeding structure, filling valve uses new normal pressure filling, ensure the filling correct and

stable,

4. Spiraling decline when output bottle, transform bottle no need to adjust the height of conveyor chains. Cap automatically.

5. Host adopts advanced PLC automatic control technology, the key electrical components from famous company such as

Japan\'s Mitsubishi, France Schneider, OMRON.

main technical parameters:

Technical data | ||||

| Model | CGF14125 | CGF18186 | CGF24248 | CGF323210 |

| Number of washing, filling, capping | 14-12-4 | 18-18-6 | 24-24-8 | 32-32-8 |

| Capacity; bottle(600ml)/hour | 3000-4000 | 5000-7000 | 8000-12000 | 12000-15000 |

| Suitable bottle size (mm) | φ=50-108 H=170-340 330ml-2.25L | |||

| Pressure (kg/cm2) | 2~3 | |||

| Power (kw) | Total motor 4.5kw | Total motor 4.5kw | Total motor 6kw | Total motor 8kw |

| Overall size (mm) (LxWxH) | 2100x1400x2500 | 2460x1720x2650 | 3100x2100x2650 | 3500x2500x2650 |

| Weight(kg) | 2500 | 3500 | 4200 | 5500 |

Technical data | |||

| Model | CGF404010 | CGF484812 | CGF606015 |

| Number of washing, filling, capping | 40-40-12 | 50-50-12 | 60-60-15 |

| Capacity; bottle(600ml)/hour | 16000-20000 | 20000-24000 | 25000-30000 |

| Suitable bottle size (mm) | φ=50-108 H=170-340 330ml-2.25L | ||

| Pressure (kg/cm2) | 2~3 | ||

| Motor power (kw) | total motor KW | total motor | total motor |

| Overall dimension(mm) (LxWxH) | 4600x1800x2650 | 5200x4500x3400 | 6500x4500x3400 |

| Weight(kg) | 6800 | 7600 | 9800 |

Introduction of our company

1. We are specialized in producing plastic machinery equipment, located in Zhangjiagang city, Jiangsu province, China.

2. There has series of high-speed mixing unit for hearting and cooling, plastic extrusion line, waste plastic recycling line and

some auxiliary machinery.

3. It is famous both at home and abroad for the top designing system and skillful technician group.

4. Welcom to visit www.cxsljx.com to know more about us.

5. We are CE and ISO certificated factory

| Packaging Detail:wooden packing |

| Delivery Detail:30days after payment |