vertical shaft impact crusher sand making machine

| Condition:New | Production Capacity:20t/h | Place of Origin:Henan China (Mainland) | Brand Name:jiaozuo xinhai |

| Model Number:VSI550 | Power(W):55KW | Weight:4200KG | Certification:ISO9001:2000 |

| Warranty:1 YEAR | After-sales Service Provided:Overseas service center available | max feeding size:40mm |

sand making machine Vertical shaft impact crusher

Brief introduction of vertical shaft impact crusher

Vertical shaft impact crusher is widely used in all kinds of minerals. It provides the high quality sand and crushed stone aggregate to the high-speed railroad, high-rise construction, municipal administration construction, water and electricity dam construction, concretes agitation station. It is the most effective machine at present. It is also applicable to crush various stones with different hardness in medium and fine crushing area. It is more advanced in intermediate hard, extra, extra hard and abrasive material crushing.

Working principle of vertical shaft impact crusher

The material falls from the upper side of machine, then into the impeller, with the effect of centrifugal force, the material was crushed with other parts of the material which shunt around the impeller in a umbrella shape. After the cross impacting, the materials will be forming an eddy current and then impact, crush with each other again, then discharging from the lower part. The whole system forms a close circuit and through multi-cycles, finally matched granularity of the final product by the control of screen set.

Features and advantage of vertical shaft impact crusher

1,“stone striking stone” working principle, high efficiency, low electricity consumption, and high efficiency crushing

2,Strong ability of through the non-crushing material, low effects by the material moisture content

3,Suitable to crush stones with mid-hardness, high hardness, and super high hardness

4,Mechanism for the production of sand, the gradation of finished product is in an adjustable fineness modulus.

5,Simple structure, low cost, easy operation/ maintenance and installation

6,Low noise and the dust pollution

7,Low weight and various installation, can be installed on mobile

Technical data

| Type | Max Feeding Size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(kg) |

| VSI550 | 40 | 5-20 | 30-55 | 4200 |

| VSI650 | 45 | 15-40 | 2×45-75 | 6780 |

| VSI750 | 45 | 40-80 | 2×75-2×90 | 10300 |

| VSI900 | 65 | 60-140 | 2×90-2×110 | 12900 |

| VSI1050 | 80 | 100-260 | 2×110-2×160 | 19800 |

| VSI1250 | 100 | 200-400 | 2×132-2×200 | 25500 |

| VSI1350 | 120 | 250-600 | 2×160-2×400 | 30600 |

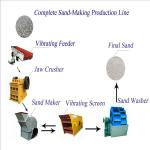

Stone production line

Company honor

Machinery of factory

| Packaging Detail:container |

| Delivery Detail:15 days |