vertical powder coating equipment for aluminum profiles

| Condition:New | Type:Coating Production Line,Vertical powder coating | Substrate:Aluminum | Coating:Powder Coating,Powder coating |

| Place of Origin:Guangdong China (Mainland) | Brand Name:ABD | Model Number:Vertical powder coating sysytem | Voltage:It depends |

| Power(W):It depends | Dimension(L*W*H):It depends | Weight:It depends | Certification:CE |

| Warranty:1 year | After-sales Service Provided:Overseas third-party support available | Place of original:Foshan hongwei | Durable in use:Durable |

| Machinery Quality:High Performance | Turnkey Project:Supply | Training:Supply |

The curing oven for aluminum profiles

powder coating booth

Specifications:

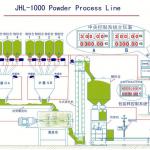

This is a powder coating line we specially designed for aluminum profiles with a long and thin shape.

Design Basis:

1. Product need to be coated: Aluminum profiles

2. Max. hanging size for each hanger: 7000*200*1800mm

3. Design conveying speed: 1.2m/min (can be adjusted from 0.8 to 2.5m/min)

4. Coating method: Auto powder spraying

5. Heat source: Natural gas\LPG (depending on you)

6. Design description:

6.1 According to the size of aluminum profiles,we design the pretreatment to be immersion tank type .

6.2 Then the pretreated workpieces will be conveyed to drying oven for water removal on their surface. The drying furnace is oftank shapewith a top-door design foreasy access of pre-treated workpieces.

6.3 After drying, the workpieces are ready for powder particle adhesion. Please manually feed them on auto powder coating line.

For a better painting result, the spray booth, waster powder recycling system, reciprocator adopts advanced equipments inChina through our careful selection. And the spraying guns, both auto and manual are imported from foreign famous company.

Some of the data for your reference:

| Item No. | Equipment Description | Quantity |

| 1 | Conveyer System (330m) | 1 Set |

| a | Main Chain ,and Rail | 1 Set |

| b | Drive Unit | 3 Set |

| c | Tension Control | 1 Set |

| d | Support Components | Some |

| e | First Hanging Tools | 1 Set |

| f | Hanging tools Self Rotating Device (1650 Pcs) | 1 Set |

| g | Automatic Greaser | 1 Set |

| 2 | Loading/un-loading conveyor system | 1 Set |

| a | Loading Transport System | 1 Set |

| b | Off-loading Transport System | 1 Set |

| c | Profile Descending Assisting System | 1 Set |

| 3 | Pre-Treatment (34.5M) | 1 Set |

| a. | Pre-Treatment Tunnel | 1 Set |

| b | Tanks | 1 Set |

| c | Horizontal Pump (MHB4 Alloy) | 9 Sets |

| d | Pipes (PVC) | 1 Set |

| e | Air ventilation system (Blowers) | 1 Set |

| f | Water Drying Oven | 1 Set |

The process of powder coating the profiles:

1.pretreatment the profiles

2.Upload the aluminum profiles

3.Drying the profiles inthe drying booth

4. Powder coating the profiles

5.Curing the profiles

6.Download the profiles

Contract people : Echo

Mobile photo:86 18988543892

Skype:echo_hongwei

| Packaging Detail:For electrical parts wooden box packed, for other components proper packing will be adopted. |

| Delivery Detail:3 months after received the deposit |