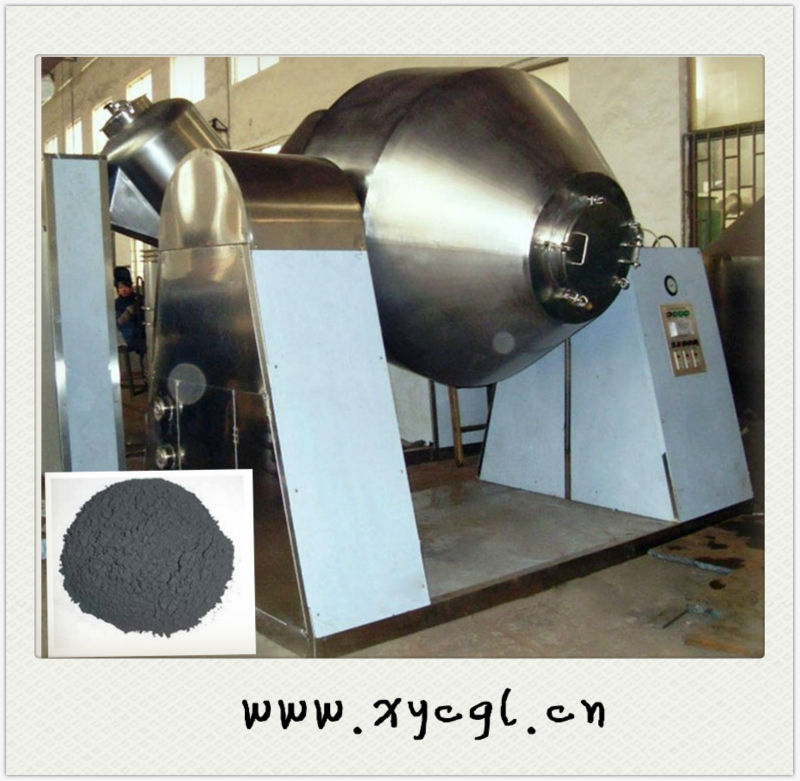

Vacuum Dryers For Manganese Oxide (MnO2)

| Condition:New | Type:Vacuum Drying Equipment | Place of Origin:Jiangsu China (Mainland) | Brand Name:SHEN YU |

| Certification:ISO9001:2000 | Warranty:three years | After-sales Service Provided:Engineers available to service machinery overseas | Heating Method:vacuum transfer |

Description:

SZG Conical Vacuum Dryer is a new generation drying device developed by our factory on the basis of combining the technology of similar equipment. Therefore it is stable in operation. The special design guarantees two shafts realize good concentricity.The main body of SZG rotating vacuum dryer is double cone tank, steam or hot water inside sealed jacket can heat the inner shell in vacuum state.As for working m edium, it may be thermal oil or steam or hot water.

Features:

1. Due to the drying is operated in vacuum, it has high speed unde r low temperature.

2. It can save resource, especially suitable for thermal sensitive materials and the materials which are easy to oxidate.

3. The equipment adopt advanced design and the inner structure is simple.

4. The drying process is sealed, thus the products don’t leak and pollute.

5. Raw material is dried and mixed in the rotation, and it can be dried to a low moisture (0.5%). Meanwhile, the final products own good uniformity.

6. Customer can select stepless regulation(1-10r/min) and step regulation(6-10r/min). It contributes to improve drying capacity.

Application:

It is widely used for drying powders, granules and fiber in chemistry and phamaceutical industry. Especially suitable for stimulating and poisonous materials.

Technical Parameter:

| model name | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | |

| volume inside the tank(L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | |

| Volume to fill raw material(L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 | |

| Heating area (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 | |

| revolution ( rpm) | 4 - 6 | ||||||||||

| power of motor (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 | |

| occupiedarea, L×W(mm) | 2160 ×800 | 2260 ×800 | 2350 ×800 | 2560 ×1000 | 2860 ×1300 | 3060 ×1300 | 3260 ×1400 | 3760 ×1800 | 3960 ×2000 | 4400 ×2500 | |

| rotating height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 | |

design pressure inside the tank (MPa) | -0.1-0.15 | ||||||||||

| design pressure of jacket (MPa) | ≤0.3 | ||||||||||

| working temp- erature(oC) | In the tank≤85 jacket≤140 | ||||||||||

| When use con- densator, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 | |

| model and power of vacuum pump | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW | |

| When don,t use condensator, | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 | |

| model and power of vacuum pump | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW | |

| Weight(kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 | |

Product Details:

| Packaging Detail:wooden case or as your requirements. |

| Delivery Detail:30 days |