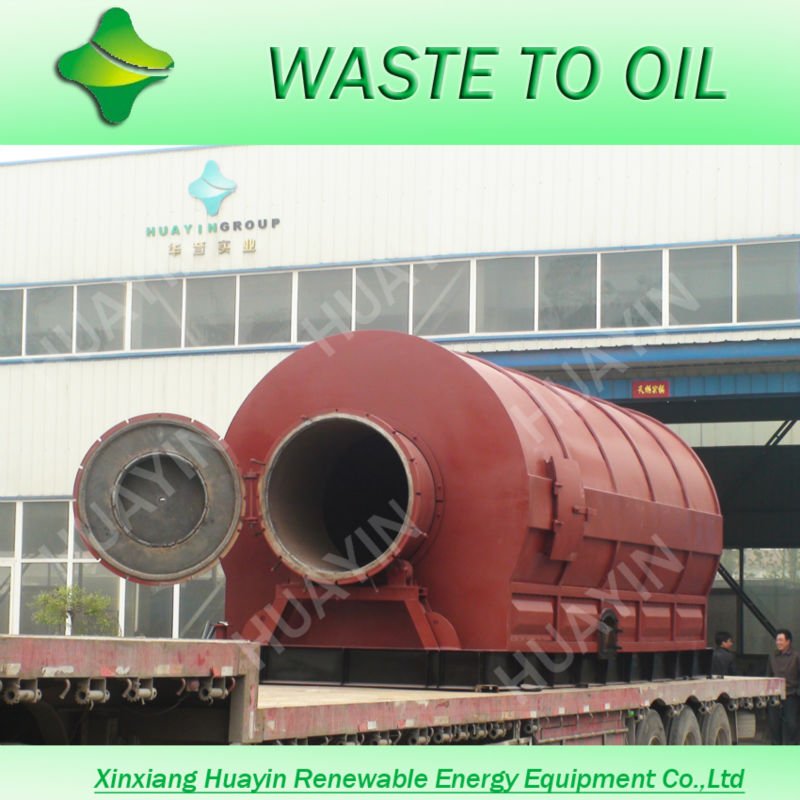

used rubber recycling machine for fuel oil

| Place of Origin:Henan China (Mainland) | Brand Name:HY | Model Number:HY-12 | Tire Machine Type:Tire Building Machine |

| Raw material:rubber/plastic/tyre | Reactor thickness:12/14/16/18mm | Safety:alarm system | Mode of cooling:water cooling |

| By-product:carbon black&steel wire |

1.working process:

Firstly ,put the raw material into furnace, seal the feed inlet system.

secondly,burn the fuel material(coal,wood,or natural gas ,oil ) in the combustion system .the reactor will slowly heat ,when the temperature reach around 250 degree celsius,it will produce oil gas .

oil gas will be processed by our technology ,then gone to cooling system to cold liquid oil.

the gas which can not liquid under normal pressure ,which will be desinged to back to combustion system to instead the fuel material to burn the reactor which can save energy very much .

after finishing oil produce ,the temperature of reactor will go down ,in the same time ,carbon black will be discharged automatically.

Lastly,when the temperature fall to 100 degree celsius,worker could open the door of reactor to discharge of steel wire, then can start another batch working.

2.Main features :

Safety:

1. With an auto welding machine for the reactor, it can not only greatly improve working efficiency but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak.

2. Vacuum system will prevent oil gas from going back to reactor and causing accident.

3. Professional thermometer, pressure gauge and safety valve.

4.It is dangerous to burn exhaust gas(C1 to C4) without any safety measures. In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1.Well water dedusting system can avoid black smoke.

2.The exhaust gas will be recycled for heating reactor, no gas pollution.

3.Every junction of the reactor is in good sealing situation with professional sealing material.

Long service life:

1.Material: Q245R special steel plate ,thickness 14mm.

2. Automatic welding machine.

3. The service life of the reactor will be 1 years.

tires recycling machine

1.We have the certification of CE, ISO9001-2001,lots of tests and lots of patents.

2.Our equipments have three links. the first link is making the crude oil and the second link is making the diesel through the fractionation. the last link is the color and oder removal.through these three links,you can get good quality oil.

3.Our equipment has lot's of advantages.

1>Security: our equipments have anti-blocking device and have pressure gauges,alarms,safety valves and vacuum machine.

2>energy conservation: recycling of exaust gas and science fire channel design can save energy and thereby reducing costs.

3>long life:hot-blast stove is long life,but not energy-saving,its consumption of energy is much greater than the repair costs of furnace.direct fired reactor is energy-saving but short life.it is a contradiction.we resolved this conflict by thickening steel plate reactor of fire approach part which oxidized extremely,so we generally use the 14mm,16mm,18mm,20mm thickness of steel plate,or12mm stainless steel plate,other slow oxidation parts use 12mm thickness plate(20G),not noly energy,but long life.

4>high degree of automation: the adance device,with a small forklift,conveyor and automatic feeder.

5>guarantee with after sales service:we has Christian background,love is the heart of our culture.selling devices not for selling only,but to help you approach to success.quality and service is our commitment and responsibility.your success is our aim.we have a good reputation in the industry.

6>low cost:all costs are low because of being located at the suburbs.advanced and complete processing equipments,almost no external processing and customer interests oriented business philosoghy,it stands to reason that the price is low.

Our factory is located in Kangcun Town, Huojia County, Xinxiang City, Henan Province. We are specializing in manufacture oil refining equipment, including waste tyre oil refining equipment, waste rubber oil refining equipment, waste plastic oil refining equipment and used oil refining equipment and so on.

We are the only factory who has Christian background in this field. All of our equipments have been pass ISO14001&ISO9001&CE. Our boss Mr. Guo has ten years of oil refining experience. ...

| Packaging Detail:40'FR + 40'HQ |

| Delivery Detail:15 days after receiving advance payment |