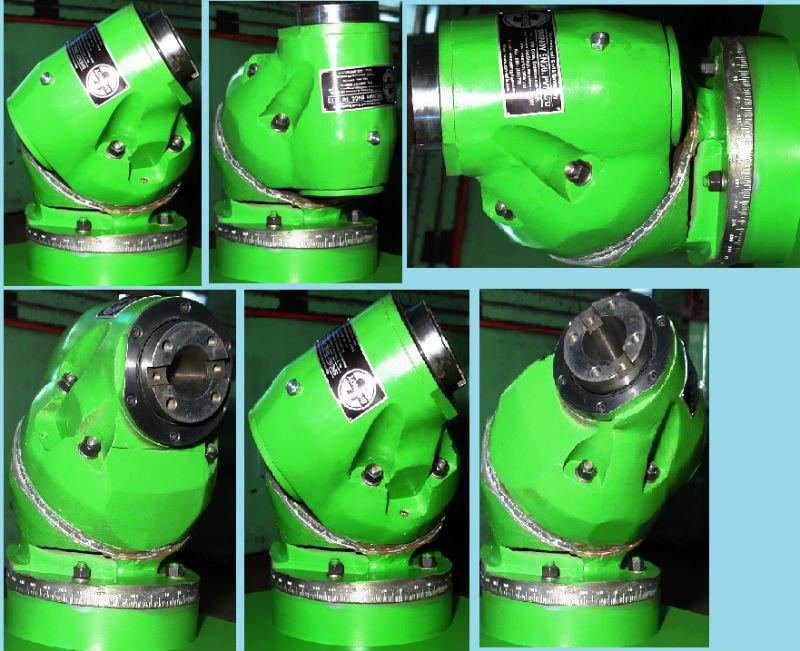

Universal milling head

| Condition:New | CNC or Not:Normal | Place of Origin:Karnataka India | Brand Name:Shenoy |

| Model Number:UMH-M | multi angle milling head:multi angle drilling head | angular right angle milling head:angular right angle drilling head | contour milling:contour drilling |

| spherical milling:spherical drilling |

| Universal milling attachment is a multi-utility attachment with spherical contouring and infinite variable orientation capabilities at any desired plane. 2 pairs of spiral bevel gears and 3rotating shafts provide 360°variable orientation facilities. Its spherical contouring capability enables it (a) to tilt±360° around the machine spindle axis (b) to tilt±360° on its own spindle axis&(c) to oscillate from front to back. In other words, the spindle of the attachment can be positioned at any desired angle - at circular planes or at oscillating plane or at a combination plane of both circular and oscillating positions. It consists of 3 modules - flange, central module and vertical module. The flange module and central module have circular T slots, so that the spindle module can tilt on the central module and the central module can tilt on the flange module. While the flange and the central modules are with horizontal axes, the angle between the central and module and vertical spindle module has an unique 45° interface. The drive system consists of 3 shafts (including the spindle) with well-designed, rigid bearing supports and with 2 pairs of bevel gears. The spindle, having ISO-50 taper, is rigidly supported by a pair of angular contact bearings in the front and a matched pair of angular contact bearings in the rear. Gears, shafts, spindles are made of case hardening steel, case hardened and ground (teeth of the spiral bevel gears are lapped). The body, consisting of 3 modules, is made of stress-relieved cast iron and conforms to Grade-25. The spiral bevel gears get located in the shafts/spindles through adequately dimensioned and ground splines. Graduated collars with least count of 1° are provided on the spindle and central module. Push button actuated hydraulic clamping and de-clamping of the cutter holding draw bar is offered optionally. Spindle bearings are lubricated for life, using the molybdenum sulfide grease. For the gears, LS 415EP-00 grease is to be used. The ratio between input and output is 1:1. The maximum recommended spindle speed and power transmission are 1000 RPM and 30 HP, respectively. The maximum dia. cutters recommended are 200 mm&150 mm in CI and MS, respectively. The attachment is integrated with the machine with the help of 4 mounting bolts and an adopter. The adopter has a male taper, which matches with the female taper of the machine spindle. The drive is through tenons. Apart from milling, other operations like angular drilling, boring etc can also be done with the Universal Milling Head. |

| Packaging Detail:as specifiied |

| Delivery Detail:3 weeks with the tailor made flange (flange cost extra) |