Ultrasonic Blister Packing Machine

Ultrasonic Packaging Machine, 1)energy-efficient, 2)economical, 3)fast, 4)environment - details see: https://www.machineto.com/ultrasonic-blister-packing-machine-10053817

| Condition:New | Automatic Grade:according to your requirement | Driven Type:Pneumatic | Place of Origin:Guangdong China (Mainland) |

| Brand Name:BRDASON | Model Number:BDS-P | Type:Packing Machine,Blister Packaging Machine | Packaging Type:soft tube and so on |

| Packaging Material:See the details |

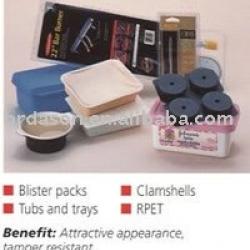

Ultrasonic Packaging Machine

Brdason's experience in the packaging industry encompasses food and beverage, consumer, and medical packaging -- and we are continually broadening our horizons.

The ultrasonic process provides many benefits for packaging; it is clean, consistent, and reliable. And:

- It is energy-efficient and economical. Energy is needed and expended only at the precise location and area of the bond site.

- There is no warm-up time and no need for constant temperature maintenance. Unlike the RF process or heat sealing, ultrasonics does not generate excessive heat.

- The ultrasonic process is up to four times faster than RF sealing. Bonding of the material usually occurs in milliseconds and requires no recovery time.

- No costly, potentially contaminating consumables, such as adhesives, staples, or solvents, are required. The resulting package is environmentally safe and recyclable.

- It can seal through contaminants (i.e., liquids, oils, powders) that may be present in the sealing area without compromising weldability.

- Ultrasonic equipment and components can be easily automated and are compatible with material handling systems.

- Microprocessor-based or customer supplied controls allow precise settings which can be changed quickly with parameter storage and recall capabilities. Advanced controls and alarm capabilities ensure optimum operation and output.

An acoustic tool called a horn transfers vibratory energy directly to the workpiece. The energy is transmitted to the joint area where it is converted to heat through friction that melts the plastic.

Based on end requirements, four basic modes of operation are used: plunge, shear, continuous, and scan. These methods can create an infinite array of packaging solutions.

Our solutions are not limited to ultrasonics. We also offer vibration and spin welding. Vibration welding is particularly useful for blister packages and works in situations where ultrasonics cannot. Spin welding is appropriate for welding fitments.

This table illustrates examples of common packaging materials (coated, laminates, and films) that can be processed with ultrasonics. The ratingsdo notrelate to the strength of the weld obtainable. We ask that you use this table as a guide only, since materials can vary from supplier to supplier. Since space prohibits the listing of all possible materials, it is possible that we can work with a material, even though it does not appear in the table. Our applications laboratory maintains a database containing over 1000 material combinations. It is likely that we have experienced your application and materials before - ask us

| Material | Coated | Laminates | Films | Blister/Clamshell |

| Ionomer (SurlynR) | G | G | G | -- |

| PET / PETE | -- | -- | -- | E |

| PETG / RPET | -- | -- | -- | E |

| Polyethylene | E | E | E | -- |

| Polypropylene | E | E | E | E |

| PVA | G | G | G | -- |

| PVC | G | G | G-P | E-G |

| Styrene | G | G | G | E |

| Urethane | E-G | -- | E-G | -- |

Key:

E = Excellent, G = Good, F = Fair, P = Poor

-- = Denotes unsuitability of process for material!

Ultrasonic equipment is available in standard welder setups or specialized configurations, depending upon your application and production requirements. Brdason understands the packaging industry and its special process needs. We have components designed for clean in place lines as well as for installation in automation. Sealing may be done in the plunge mode, or continuously as shown in the In-Line Packaging system below. Whatever your need, we can provide the solution!

| Packaging Detail:standard wooden packaging |

| Delivery Detail:within 10 days after the receipt of payment |