UHT milk processing equipment manufacturing plant

| Condition:New | Place of Origin:Shanghai China (Mainland) | Brand Name:Jimei UHT milk processing equipment manufacturing plant | Type:Processing Line,UHT milk processing equipment manufacturing plant |

| Certification:CE GAP ISO9001 | Warranty:365 days and lifelong technical support | After-sales Service Provided:Engineers available to service machinery overseas | Material:SUS304 |

Specifications

2.CE compliant

3.CIP cleaning system

4.pasteurizer and homogenizer

5.MOQ:1set

UHT milk processing plant

As a professional milk and juice production line supplier, we can design,

manufacture, install milk production line and milk plant for producing all kinds of dairy products, such as pure milk, flavored milk, sour milk, yogurt, milk drinking and ice cream, butter, soy milk, tea drinking, energy drinking and so on.

The whole milk production line includes the following units:

1. Milk reception or powder & water mixing unit.

This part is to prepare and mix the raw material. If the fresh milk is in urgent need or not enough for production, powder milk can be used to replace it.

2. Mixing and sugar melting unit.

Mixing machine and heat system are needed to melt the sugar and supply hot water, and then before entering the mixing tank (blending tank) for further mixing, the syrup should be cooled.

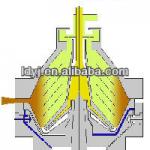

3. Pasteurizer and homogenizer.

This part is to kill the bacteria, thus ensuring the safety of products.

The homogenizer is used to make the products more homogeneous which can help to improve the quality and prolong the shelf life of products.

The degasser is used to remove the air that is mixed in the product. According to different products types and filling types, the pasteurizer is strictly chosen to suit the plant.

4. Storage or yogurt producing unit.

5. Filling or packing unit.

We can provide many kinds of filling types, such as plastic bag, PRT bottle, HDPE bottle, glass bottle, gable bottle, and plastic cups and so on. You can choose what you want.

6. CIP cleaning system.

7. After treatment equipments such as conveyer, package or pallet etc.

8. Some assistant equipments like steam boiler, air compressor and cold water unit etc.

9. Materials for the product pipes installation, power pipes installation and

also electrical installation.

Only a simple sample is mentioned above.

We can design and manufacture whole line of milk, juice production line which is called turnkey projects, according to your requirement.

The capacity of our plant can be 2T-300T/D.

Products types can be of 1 or 2 or more kinds.

Filling types can be decided by customer.

This production line ,which made by JIMEI mainly includes the following machines:

1. Milk weighing tank

2. Milk collection tank

3. Direct-cooling milk storage tank

4. High-speed mixing tank

5. High-speed homogenizer

6. UHT instant sterilizer

7. Aseptic tank

8. Plate heat exchanger

9. Side sealing machine

10. CIP cleaning device

11. Return pump

12. Steam boiler

Terms and Conditions:

1. Package- all equipments packed in wooden cases worthy of sea shipping.

2. Payment- 30% of total amount paid by T/T in advance and the balance paid by T/T after inspection and before shipment.

3. Delivery- in 60 days upon receipt of down payments.

4. Warranty-all machines & equipments are of one year warranty and life long maintenance offered by seller.

5. Installation- the seller arrange engineer to set up the equipments and train the operation workers for free, till qualified products are produced and maintenance in normal running, the buyer bear the round air tickets and local accommodation for the seller's engineer.

More details:

Company profile:

Jimei company was established in 1989, and for years we have been focusing on the improvement in machinery theory and performance in the food machinery industry. We have passed ISO9001, National GMP Technology Standard Evaluation, inspections by National Pharmaceutical Equipment Inspection Center, and all products are designed and manufactured strictly according to standards such as ISO, SMS, IDF, DIN, QB/T2003, 2004, 3A as well as our internal standards.

We are a company integrating scientific research, manufacturing and service, and have the best manufacturing facilities and production process, professional staffs, imported facilities of concentration distill series, automatic CIP series, PLC control etc. Now we have been a market leader in the Chinese food machinery industry.

Jimei company keeps in mind the tenet of "serving users" and focus on research and development of new technologies. It has comprehensive development capacity and sound quality assurance system, and has made R&D achievement and obtained invention patents.

Our machinery are widely sold in China, and exported through our sister compang in group (Shanghai Runrong International Trade Co., Ltd)to Asia, Europe, America, Africa, over 50 countries, and gained favorable feedback from users.

We are specialized in turn key project solution of various complete production lines for pasteurized milk, UHT milk, milk powder, yoghurt, ice cream, fruit juice, tea drinks, carbonated drinks, mineral and pure water, etc. And all kinds of beverage processing machinery that combined to form for a plant, like milk preliminary handling, UHT pipe, plate bacteria killing machines, bacteria-free liquid soft packing machine, gable-top paper box filling machine etc.

We have provided products to the following famous companies: Taizinai, Wahaha, Sanlu, Bright, Danone, Mengliu, PepsiCola, Yingxiong etc.

| Packaging Detail:UHT milk processing equipment manufacturing plant in nylon cloth and film wrapping. |

| Delivery Detail:30 days UHT milk processing equipment manufacturing plant |