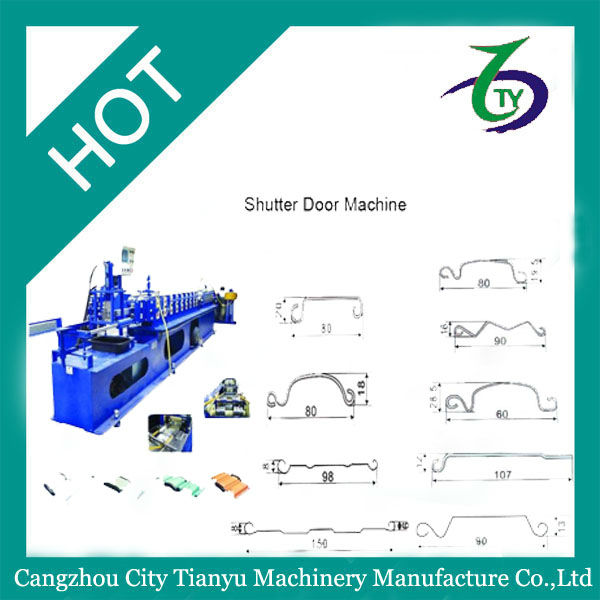

TY roller shutter door roll forming machine/roller shutter door making machine

| Condition:New | Type:Tile Forming Machine,roll forming machine | Tile Type:Colored Glaze Steel | Use:Roof |

| Production Capacity:15-16m/min | Place of Origin:Hebei China (Mainland) | Brand Name:Tianyu | Model Number:TYroller shutter door |

| Power(W):8KW | Voltage:380V,50HZ,3phase | Dimension(L*W*H):6500*800*1200mm | Weight:about 2.7T |

| Certification:CE | Warranty:one year warranty | After-sales Service Provided:Engineers available to service machinery overseas | machine color:according to your requirement |

| Roller station:13 rows | Type of cutting:hydraulic cutting | Thickness of frame:14mm | Shaft Diameter:75mm |

| Raw Material:colored steel or galvanized steel | Thickness range:0.2-0.7mm | Coil Width:according to your requiremtns | Cover Width:according to your requiremtns |

TY roller shutter door roll forming machine/roller shutter door making machine

1.Main Accessories of theroll forming machine

| 1 | Decoiler(manual or hydraulic for options) | 1 set |

| 2 | Feeding device | 1 set |

| 3 | Main Forming Machine | 1 set |

| 4 | Hydraulic cutting device | 1 set |

| 5 | Hydraulic Station | 1 set |

| 6 | PLC computer control system | 1 set |

| 7 | 4m Run Out Table | 1sets |

2.Main Technicial Parameter of theroll forming machine

| 1 | Inner diameter of manual decoiler | 500mm |

| 2 | Outer diameter of manual decoiler | 1000mm |

| 3 | Weight capacity of manual decoiler | 1.5T |

| 4 | Appearance Size | 6500mm*800mm*1200mm |

| 5 | Raw Material | colored steel or galvanized steel/steel |

| 6 | Roller material | high grade 45# forged steel,polished,heated,quenched |

| 7 | Blade Material | CR12 with polished |

| 8 | Chrome Coating | coated with 0.05mm hard chrome |

| 9 | Control System | PLC control |

| 10 | main motor power | 4KW |

| 11 | Hydraulic Power | 4 KW |

| 12 | Roller station | 13 rollers |

| 13 | Material of chain | high grade 45# steel:polished,heated,quenched HRC 45-50 |

| 14 | Speed of Product | 15-16m/min |

| 15 | Thickness range | 0.5-1.2mm |

| 16 | Type of cutting | hydraulic cutting |

| 17 | Coil Width | according to your requirements |

| 18 | Cover Width | according to your requirements |

| 19 | Material of rack | complete welded structure of A3 steel plate |

| 20 | Machine frame stand | welded with 300H-steel |

| 21 | Type of forming machine | single station with chain transmission |

| 22 | Thickness of frame | 14mm |

| 23 | Shaft Diameter | 75mm |

| 24 | Weight | about 2.7T |

| 25 | Voltage | 380V 50HZ 3Phases( or as your local requirement) |

| 26 | Electrical control | PLC frequency control system |

TY roller shutter door roll forming machine production show

Our company has found for over 1 7 years since 1 9 9 6.

We are the professional manufacture to produce different kinds of roll forming machine,

such as roof and wall panel forming machine,c/z purlin forming machine,s

andwich panel production line,floor deck forming machine,light steel keel forming machine,

container board forming machine,bending machine,cutting machine and so on.

What's more, equipment can be specially designed and

manufactured at customers' requirements.

Fine quality as well as low price.This new product is

to the taste of world market.

Products Warranty: 12 month, and we will provide

the technical support for the whole life of the equipment

| Packaging Detail:1.Tighten to container with steel wire rope and welded machine with container by angel iron 2. Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic) 3. PLC control system and motor pump are packed with water proof paper coverage |

| Delivery Detail:30 days after receiving the deposit |