Two piece can production line,Two Piece Can

| Type:Packaging Line | Condition:New | Application:Food | Packaging Type:Cans |

| Packaging Material:Metal | Automatic Grade:Automatic | Driven Type:Electric | Place of Origin:Guangdong China (Mainland) |

| Brand Name:CHINA HANJIANG | After-sales Service Provided:Engineers available to service machinery overseas | Color:Grey | Certificate:EU CE & ISO9001:2000 |

| Usage:Two piece can making Machine |

Two Piece Can Making Line

1.Brief introduction

Our companyCHINA HANJIANGlocated in shantou guangdong,a beautiful city.After 20 years' delevepments, we desin and manufacture production line for various metal containers, includingbeverage cans, food cans, milk powder cans and chemical cans.

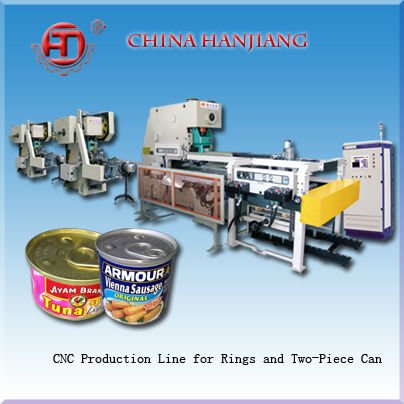

2. Automatic Two-Piece Can Making Line

CNC Punching production line is for the purpose of cap-making and two piece can body-forming.It is comprised of Automatic sheet feeder, CNC Feeding System, Auto Punching machine (press), Tooling, Belt Conveyer, (options: Curler, lining and drying machine, Scrap Collector, safety fence,etc)

Our line is including the following device:

(1)Schneider Touch screen &servo, electric control system;

(2)Automatic feeder;

(3)Automatic feeding system

(4)Automatic CNC numerical control system;

(5)"C" type press or portal type press;

(6)operation mould (high -precision, you can choose carbide material );

(7)Conveyer;

(8)Scrap collector

(PS:Contact us to get more detail!)

3.Advantages

1).More than20 years experienceand reputation both at domestic and abroad market;

2).Quality Assurance, excellent after service and reasonable price;

3).Reliable andsafeto control,easyto operate and maintain;

4).High speed, high production efficiency. save labors.

5).Equipped with human-computer interface and PLC; adoptdigitalcontrol technology;

6).Full automatic, multi-functional and multi mould, suitable for different two piece can or lid diameter, etc.

7).Using the following well-known parts:

| Name | Brand | |||

| Electro valves, Micro valves, Pneumatic valves,reducing valve | Festo(Germany) and SMC | |||

| Bearing | Japanese and Germany Brand | |||

| Electrical appliance ,PLC | Omron(Japanese) | |||

| Roller forming | Sweden | |||

| Frequency transformer | Schneider(French) | |||

| Belt | Italy | |||

| Blowing system | Festo(Germany) | |||

| Hard Alloy | Sweden | |||

8). Using American CNC parts processing machine (HAAS) to ensures our machine quality and high precision parts matching with each other.

4.The Picture of Automatic Two-Piece Can Making Machine

(PS: sorry for the fuzziness pic, please call us for more detail,^-^!!)

5.Our company

China Hanjiang is established in 1992, specialized in the research, development at manufacturing of can-making machine. With the dedication on quality and innovation on technology, China Hanjiang has become the leading enterprise of can-making machine in China. We design and manufacture production lines for various metal containers, including beverage cans, food cans, milk powder cans and chemical cans.

Thank you very much, we will sincere service for you! If you want to know more detail,please call me now!

| Packaging Detail:standard packaging |

| Delivery Detail:3-4 months |