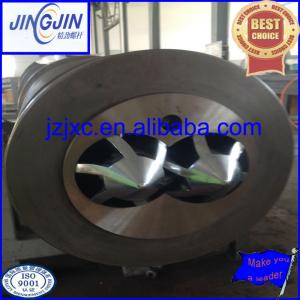

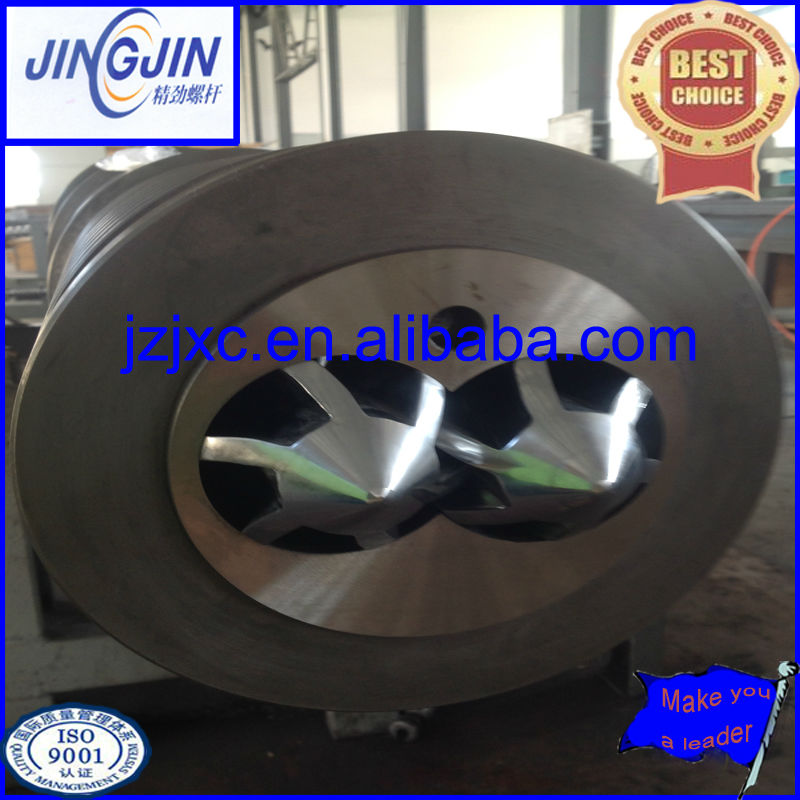

twin parallel screw barrel / parallel twin barrel screw

| Place of Origin:Zhejiang China (Mainland) | Brand Name:Jingjin | Model Number:JJ-PA-0051 | Base material::38CrMoAlA; SKD61; SKD11; 40Cr; 42CrMo; high quality alloy steel |

| Screw barrel hs code::8477900000 | Screw barrel Certificate::ISO9001:2008 | Surface treatment::Nitrition,Quenching,Alloy coating spraying,Hard-chrome plating | Surface Hardness::>950HV |

| Surface Roughness::Ra0.4um | Nitriding treatment::more than 100 hours | Thickness of nitriding layer::0.5-0.8mm | Hardness after Hardening & Tempering::HB260-300 |

| Nitrition brittleness::less than grade2 |

twin parallel screw barrel / parallel twin barrel screw

(Co-rotating and Counter-rotating)Parallel twin screw :

| Φ35/2 | Φ45/2 | Φ50/2 | Φ55/2 | Φ60/2 | Φ65/2 |

| Φ70/2 | Φ75/2 | Φ80/2 | Φ85/2 | Φ90/2 | Φ100/2 |

| Φ110/2 | Φ120/2 | Φ130/2 | Φ140/2 | Φ150/2 |

Advantages:Screw&barrel also can be made:CINCINNATI, BATTENFELD, KRUSSMAFFEI, BAUSANO and AMUT model spares!According to different material and plastic product to choose different compress rate and L/D!

(If you don't see the paricular model you want,pls tell me to discuss your needs.we can provide you with perfect solution to meet your demands.

1. Parallel twin screw and barrel has the advantage of lower rotation speed, smaller shear stress between the small screw.

2. Good plasticization, high productivity, small shear force, stable pressure , less wear and tear and low cost.

3. Parallel twin-screw and barrel is widely used in PVC products processing, especially for the production of PVC products with the output over 350Kg / h, because the parallel twin-screw and barrel costs less than conical twin-screw and barrel while it has more mature technology.

4. Parallel twin-screw and barrel is successfully applied in PVC plate, pipe, profile, pellet and mould, at the same time, it solved the technical problem of low foaming, high foaming, high filling, wear and corrosion.

Detailed Technical Information

| Base Material | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) 5)9Cr18MoV |

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 4)NiCo-based alloy |

| Bimetallic Alloy level | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 9.5% |

| Designing | Screw structure and compression ratio can be designed according to different products & different clamping force requirement. |

| Treatment Technology | 1)Longer time Gas Nitriding treatment 2)special anti-wear & abrasion alloy (bimetallic) 3)tungsten carbide 4)cobalt base alloy 5)stainless steel 6)Gh113 nickel based alloy Treatment Nitriding treatment(>100 Hours) Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: >950Hv Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.03-0.08mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-65° |

| Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule),etc |

| Basic Infomation | L/D:10-40 screw diameter:Φ14-Φ300*8000mm Surface Roughness :Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Hardness after Hardening & Tempering: HB260-300 Fragility of Nitration:≤Two grade |

| General Terms | Means of transport: Ocean,Air,Express Production time: About 20 days after we receive the deposit and lead time will different according to the order quantity. |

| Warranty period | 2-4years(Depends on the plastic raw materials) Bimetallic: much longer lifetime. |

| Competitive Edge | 1.Long lifetime,low energy consumption. 2.Wonderful plasticizing 3. Top-quality bimetallic screw and barrel 4. High wear resistance, resistance to corrosion 5. Fast and On time delivery 6. Best customer after-sale service! |

Outstanding Features of Bimetallic Screw and Barrel:

Hardness HRC55-65 Outstanding corrosion-resistance.

Hardness layer reaches above 2mm thickness. Hardness does not decrease with depth.

Hardness does not decrease under normal temperature.

Abrsion resistance / wear resistance on the hardened layer is 2~3 times higher than that treated by conventional heat treatment.

We specialized in manufacturing many types of screws, the barrels can be applied on all types of injection moulding machine,rubber hot-feeding extruder, rubber cold-feeding extruder, pin barrel cold feed extruder, plastic extruder with different specifications for Haitian,Demag,Toshiba, Husky, Nissei etc.We can provide the models of screw including variable pitch and variable depth, variable pitch and equal depth, variable depth and equal pitch, and equal depth and pitch.Groove multi-die type, composite type, mixing type and separating type.

Screw barrel shows

Walk into Jingjin:

SCREW BARREL PACKING:

Final products

Our GLOGRIES:

our certifications

Our performance excellence

| Packaging Detail:film wrapped in wooden case without fumigation(export standard) |

| Delivery Detail:20 working days upon receipt of 30% deposit |