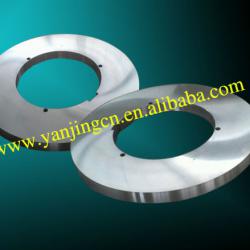

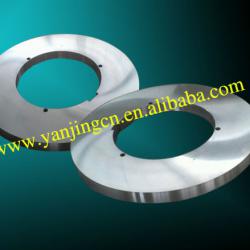

tungsten carbide shear blade/tungsten carbide rotary blades/hard alloy blade/rolling blade

| Place of Origin:Anhui China (Mainland) | Brand Name:Yanjin |

Company profile:

Ma’anshan Jinhai Metallurgical Machinery Manufacturing Co.,Ltd established in 1988,is one of the leading enterprise specializing in the production of various cutting tools ,including shearing blades, large metallurgical knives,wear resistance castings,metallurgical spare parts ,etc. At present,from to finishing,all steps are carried out in the company.Occupying an area of 55,000 square meters,Jinhai company have more than 180 employees and no less than 140 sets of processing equipment. Even early in 1996,the company established its R&D department and developed independently H13K,HMB and HMK high alloy serious with the features of high intensity,high hardness,high toughness,etc. Besides patented materials ,normal raw materials are also available in this company, like 9CrSi,6CrW2Si,H13,D2,etc. Suitable materials,skilled producing process and responsible after-sale service make our products popular at home and abroad.

Enterprise spirit:

Mutual beneficial cooperation

Corporate Philosophy :

Timely ,Effective,Standardized and High Quality

Advantages:

1,Superior Price Performance,

2,Transpositional Consideration,

3,All-around service,

4,Punctual date of delivery,

5,Electric Slag Remelting after medium frequency furnace to make products more pure which is different from other enterprises,

6,Rough forging and precision forging after Blanking to make products’ organization structure more tightness and refine crystal grain,

7,More choice for raw materials such as Cr12MoV,D2,H13, high-speed steel,especially we have patent in H13K,HMB,HMK.

8,Double quenching in the process of Heat Treatment which is important about the hardness.

Testing equipments:

Spectrometer, Rockwell Hardness Tester, Leeb Hardness Tester, Impact Testing Machine, Metallography Analyzer, Ultrasonic Harmless Flaw Detector, Carbon and sulfur analyzer, Tensile Tester, Magnetic Powder Inspection, Caliper rule, Microcalliper rule,etc.

Manufacturing machines:

Steel-making: Medium frequency furnaces, Electric melting furnaces,

Forging: Air hammer, Electro-hydraulic hammer,

Rough Processing: CNC Lathe, Sawing machine, Slotting machine, Milling machine, Facing machine, Drilling machine,

Heat Treatment: Salt bath furnace transformer, Well type resistance furnace, Bogie-hearth resistance furnace, Chamber type electric resistance furnace, Lift platform, Homemade tempering furnace, Homemade oil burner, Suction Ventilator, Bell type heat furnace

Precision Processing: Internal grinder, External grinder, CNC grinder, Electric spark CNC wire-cut,etc.

Industry(Yanjin Metallurgical Industrial Blades for following industries):

Arts and Grafts; Auto Glass;Ceramic Dicing;Converting;Fiber;Food;Hunting;Industrial;Magnets;

Medical;Packaging;Customized blades.

Application(Yanjin blades can be used in the following cutting):

Paper cutting;Extrusion\Cut-off;Film and Foil slitting;Fiber cutting;Mat cutting;Plotting;

Fiberglass;Trimming;Plastic;Printing;Rubber;Sign making;Surgical\Scalpel;Tile cutting.

Materials(our broad of choice of materials available):

High Carbon; Stainless Steel; High Speed Steel; Special Alloy; Tool Steel; Tungsten Carbide;

Diamond; Metal-bonding; Cr12MoV; H13; H13K; HMB; HMK

To customers:

What to cut? Where to use? How to cut? Just tell us your requirements, Yanjin will offer you the most professional cutting solution and design!We enjoy the opportunity to make the best blades and exceed your expectations.

There is no single perfect material. Many factors are involved in selecting exactly the right material to match your cutting application. Skill and experience are necessary to know what material best suits you for your application, environment, process, etc.

Our goal is to provide you a blade that gives you the maximum cutting quality at the most cost efficient price. Material selection is an important part of this equation. With that in mind, Yanjin is happy to provide the following as a guide in the best material selection for the job:

· Availability

· Durability

· Rust resistance

· Cutting process

| Packaging Detail:Applid with anti-rust oil in plastic bag will be kept in plywood case (or as customer's request) |

| Delivery Detail:nearly 30 days |