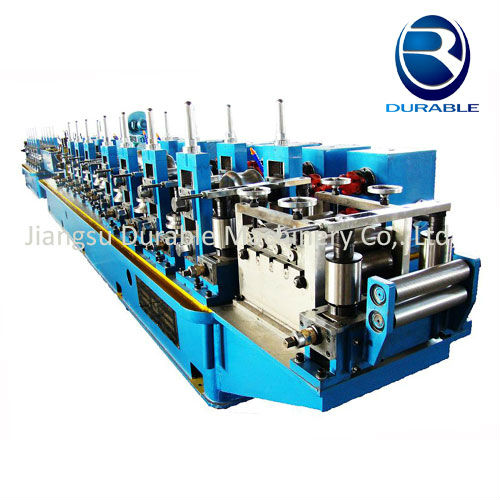

Tube Machine for Steel Tube Produce

| Condition:New | Type:Pipe Mill | Pipe Material:Carbon Steel | Application:Thick structural tube |

| Place of Origin:Jiangsu China (Mainland) | Brand Name:HC | Model Number:90 | Voltage:380V/415V |

| Power(W):600 | Dimension(L*W*H):65mx6m | Certification:ISO9001 | Warranty:1 YEAR |

| After-sales Service Provided:Engineers available to service machinery overseas |

Tube Machine for Steel Tube Produce:

Steel Tube Machine is designed to produce welded round tubes of 0.3~8.6 inch in diameter and 0.2~8mm in wall thickness as well as square pipes, rectangular pipes and irregularly shaped pipes of corresponding sizes. Our machines are with high speed, high production, good performance, low labor cost and cost saving.

Description:

1. HC90 Carbon Steel Pipe Welding Machine is designed to make round pipe ,square pipe ,rectangle pipe and other oval abnormal pipes.

2. Main Motor: 264KW

3. Main Unit Size: Length 4-12m

4. Pipe Range: 35-100mm.

5. Wall Thickness: 1.2-4.0mm.

6. Welding Speed: 0-65m/min.

7. Type: HC90

More models:

| Equipment Type | HC50 | HC60 | HC76 | HC90 |

| Pipe diameter | 20-63.5mm | 25-76mm | 32-89mm | 35-100mm |

| Thickness | 0.8-2.75mm | 1.0-3.2mm | 1.2-3.75mm | 1.2-4.0mm |

| Producing speed | 0-70m/min | 0-70m/min | 0-70m/min | 0-65m/min |

| Main engine power | 150kw | 180kw | 264kw | 264kw |

| High frequency power | 200kw | 250kw | 300kw | 300kw |

Main functions:

HC50, HC60, HC76 Tube machine are mainly applied in manufacturing frametubes and fitness equipment tubes.

HC90 Tube machine line mainly applied in manufacturing thick structural tube.

Not only the round pipe but also the rectangle tube mill we supply. The OD, ID, thickness, we can supply the machine as our custom's requirement. Also, We are a professional mould producer for 7years. We are so good at this tube mill/ pipe machine area in China.Plz, dont hesitate to contact us, If you need any help.

Specification:

Main Technical Parameters | |||||

| Model | Diameter of round pipes(mm) | Wall thickness of welded pipes(mm) | Speed of pipe welding(m/min) | Power of major motor(KW) | High frequency power(KW) |

| HC10 | Φ0.3~Φ0.6inch (Φ7mm~Φ16mm) | 0.2~0.8mm | 0~80m/min | 15KW | 60KW |

| HC20 | Φ0.3~Φ1.0inch (Φ8mm~Φ25mm) | 0.3~1.2mm | 0~80m/min | 30KW | 100KW |

| HC25 | Φ0.3~Φ1.4inch (Φ8mm~Φ32mm) | 0.4~1.5mm | 0~80m/min | 37KW | 100KW |

| HC28 | Φ0.4~Φ1.5inch (Φ10mm-Φ38mm) | 0.4~1.8mm | 0~80m/min | 45KW | 100KW |

| HC32 | Φ0.5~Φ1.7inch (Φ12mm~Φ42mm) | 0.4~2mm | 0~70m/min | 55KW | 100KW |

| HC45 | Φ0.5~Φ2.0inch (Φ13mm-Φ50mm) | 0.4~2.2mm | 0~70m/min | 75KW | 150KW |

| HC50 | Φ0.8~Φ2.5inch (Φ22mm~Φ63mm) | 0.6~2.75mm | 0~65m/min | 90KW | 200KW |

| HC60 | Φ0.8~Φ3.0inch (Φ22mm~Φ76mm) | 0.8~3.5mm | 0~65m/min | 110KW | 200KW |

| HC76 | Φ1.3~Φ3.7inch (Φ32mm~Φ95mm) | 1.5~4mm | 0~60 m/min | 160KW | 300KW |

| HC89 | Φ1.5~Φ4.5inch (Φ38mm~Φ114mm) | 1.5~4.5mm | 0~55m/min | 200KW | 300KW |

| HC114 | Φ2.3~Φ5.0inch (Φ60mm~Φ127mm) | 2~5mm | 0~50m/min | 250KW | 400KW |

| HC165 | Φ3.0~Φ6.5inch (Φ76mm~Φ165mm) | 2~6mm | 0~50 m/min | 160*2KW | 600KW |

| HC219 | Φ4.5~Φ8.6inch (Φ114mm~Φ219mm) | 3~8mm | 0~40m/min | 200*3KW | 800KW |

| Packaging Detail:Standard Export Packing |

| Delivery Detail:2 months |