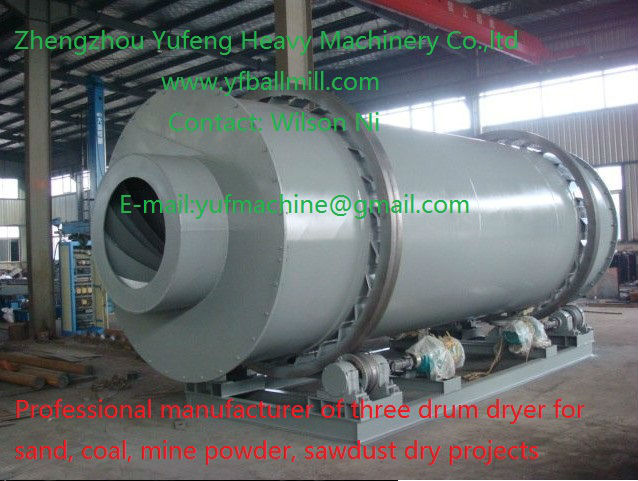

Triple Pass rotary drum Dryer 3-Drum Dryer/Drum Dryer/Coal Rotary Dryer/Sand Rotary Drier

| Condition:New | Type:Drum Drying Equipment,rotary drum dryer | Place of Origin:Henan China (Mainland) | Brand Name:Yufeng |

| Model Number:rotary drum dryer/ triple pass dryer | Voltage:as required | Power(W):as required | Dimension(L*W*H):as required |

| Weight:as required | Certification:ISO9001:2008 | Warranty:18MONTHS | After-sales Service Provided:Engineers available to service machinery overseas |

| process:rotating drying | heating source:coal, wood, oil, natural gas | capacity:2-100t/h | dry technology:full around support |

Rotary drum DryerMachine is widely used in building materials, metallurgy, chemical industry and cement industry, which is widely used to dry the stuff such as limestone, coal powder, slag and clay.

1.dryer anti-overload, large capacity, low fuel consumption, low-cost drying;

2.the downstream drying, flue gas and the wet material into the dryer on the same side, can take advantage of the high temperature flue gas to get high evaporation, dryer outlet temperature, high thermal efficiency;

coal rotary dryer is developed based on the rotary dryer. It can be widely used in:

1.The coal industry: Coal slime, coal, flotation clean coal, mixed clean coal etc.

2. The construction industry: Blast furnace slag, clay, bentonite soil, lime stone, sand, quartz stone etc.

3. Ore processing industry: Various metal concentrates, slag, tailings etc.

4. Chemical industry: Non-drying heat sensitive materials

Coal slime rotary dryeris a kind of stable and reliable heating drying equipment, designed to dry materials of high moisture and strong stickiness, such as coal slurry, mud, gypsum, humid swell soil, electroplate mud and so on. The performance of coal slime dryer is better than tube rotary dryer and blade rotary dryer.

rotary dryer special features:

- · Drying material with co-current or counter-current hot gas, the heating efficiency can be up to 95%.

- · Coal Slime dryer should be operated under high temperature and low oxygen to avoid materials being burnt when drying.

rotary dryer main applicable areas:

- 1. Coal industry: drying coal, coal slime, coal with flotation, drying mixed coal;

- 2, Construction industry: drying cinder, blast furnace slag, clay, limestone, sand, quartz;

- 3, Mining processing industry: drying metal concentrates, slag, tailings;

- 4, Chemical industry: heat non-sensitive materials.

Specification | Shell Size (m) | Capacity (T/h) | Initial moisture(%) | Final water (%) | Total power (kw) |

GT1.6-16.5 | Φ1.6*16.5 | 3-5T/h | 20±3 | ≤10 | 57 |

GT1.8-18 | Φ1.8*18 | 5-7T/h | 20±3 | ≤10 | 60.5 |

GT2-20 | Φ2.0*20 | 7-10T/h | 20±3 | ≤10 | 80 |

GT2.2-20 | Φ2.2*20 | 10-15T/h | 20±3 | ≤10 | 95 |

GT2.5-22 | Φ2.5*22 | 15-20T/h | 20±3 | ≤10 | 108.5 |

Three Cylinder DryerTechnicial Parameters

| Model | 2x4.5m | 2.2x5m | 2.5x6m | 2.7x6.5m | 3.0x6.5m | 3.2x7m | 3.6x8m | 4.2x8m |

| Diameter of outer cylinder(m) | 2 | 2.2 | 2.5 | 2.7 | 3 | 3.2 | 3.6 | 4.2 |

| Length of outer cylinder(m) | 4.5 | 5 | 6 | 6.5 | 6.5 | 7 | 8 | 8 |

| Cylinder volume(m3) | 14.13 | 18.99 | 29.43 | 37.19 | 45.92 | 56.27 | 81.39 | 110.78 |

| Cylinder speed(r/min) | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 |

| Max. inlet temperature | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 | 700-750 |

| Capacity(t/h) | 13-18 | 15-23 | 20-28 | 24-33 | 35-40 | 40-60 | 55-75 | 70-120 |

| Motor power(kw) | 5.5x2 | 7.5x2 | 5.5x4 | 7.5x4 | 11x4 | 15x4 | 18.5x4 | 22x4 |

ABOUT US

Zhengzhou Yufeng Heavy Machinery Co.,ltd.is a moden enterprise, manufacturing large-size and medium-size mining equipment which has been exported to various countries and owns high reputation. Our products mainly include:

Drying equipments:sawdust dryer, wood chips dryer, sand dryer, coal dryer, mine powder dryer, sludge dryer, fibre dryer

Welcome to Zhengzhou YUFENG Machinery Company.If you want to more information about ourRotary Dryer, Please give us the message, we will reply as soon as possible.

| Packaging Detail:1.export standard container 20GP or 40 GP, 40HQ, FR container, in bulk. 2. The spare parts in wooden case 3. Or as your requirement |

| Delivery Detail:25-40working days as per the contract |