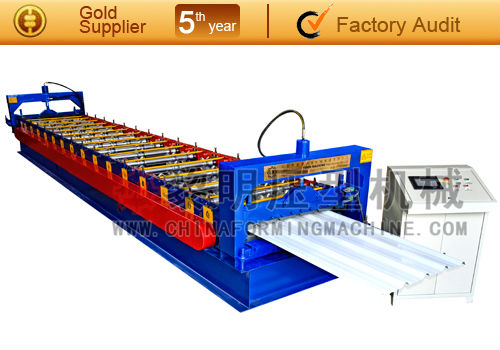

Trapezoidal Roofing Sheet Roll Forming Machine

1.ISO 9001:2008 certificate, 2.Customizable profile, 3.Stable working, 4.Easy operation, 5.Protective device for worker's safety - details see: https://www.machineto.com/trapezoidal-roofing-sheet-roll-forming-machine-10099006

| Place of Origin:Hebei China (Mainland) | Brand Name:LIMING | Model Number:LM-760 | Type:Trapezoidal Roofing Sheet Roll Forming Machine |

| Usage:Roof panel | Color:Blue or green |

1.Working Flow of Trapezoidal Roofing Sheet Roll Forming Machine LM-760:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→Auto cutting→Products receiving

2.Main Parameters of Trapezoidal Roofing Sheet Roll Forming Machine LM-760:

| No. | Item | |

| 1 | Processing material | PPGI,GI |

| 2 | Input width(mm) | 1000 |

| 3 | Formed width(mm) | 760 |

| 4 | Processing thickness(mm) | 0.3-0.6 |

| 5 | Material of rollers | No.45 steel,with hard chrome coated |

| 6 | Diameter of shaft | Φ70mm |

| 7 | Production speed | 15-20m/min |

| 8 | Roller driven | Decelerating motor + chain transmission |

| 9 | Cutting model | Hydraulic profile cutting |

| 10 | Length measurement | Encoder |

| 11 | Control style | PLC |

| 12 | Operate model | Button+touch screen |

| 13 | Total power | 6kw |

| 14 | Voltage | 380V 50HZ or as quested |

3.Components of production line:

a.Manual uncoiler,loading weight 5000kgs(electric or hydraulic uncoiler for your choice)

b.Feeding platform

c.Roll forming machine

d.Computer control cabinet

e.Hydraulic station

f.Encoder

g.Run-out tables

Rollers' Process: Assembling:

Inspection: Delivery:

Our certificate:

Please contact us for more detailed information!

| Packaging Detail:Bare packing,computer control cabinet is to be boxed. |

| Delivery Detail:35 working days after receiving advance payment. |