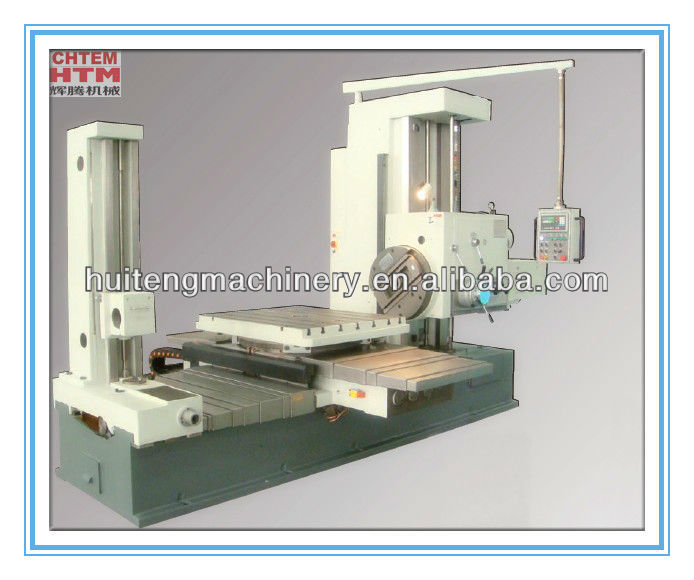

TPX 6111A Horizontal Boring

| Condition:New | CNC or Not:CNC | Production Capacity:High | Place of Origin:Shandong China (Mainland) |

| Brand Name:CHTEM | Model Number:TPX6111A | Voltage:According to clients' site voltage | Power(W):7.5 kw |

| Dimension(L*W*H):Worktable size: 1140x1000 | Weight:Max. weight of workpiece: 2.5 ton | Certification:ISO9001:2008; CE Certificate | After-sales Service Provided:Engineers available to service machinery overseas |

| Type:Horizontal Boring | Material:High grade case iron | Production period:2-3 months | Package:Fumigated wood cases |

| Transportation:Seaway or railway | Guarantee:One year guarantee | Color:Blue and grey | Payment methods:T/T; L/C |

| Trade terms:FOB; CIF; CFR; DDP;ect. | Functions:Boring; Milling; Reamin; Drilling |

Horizontal Boring TPX613A (Designed and made in Qingdao, Shandong China)

1.Main specification

| Main specifications | Unite | TPX6111A |

| Spindle diameter | mm | 130 |

| Spindle taper | Metric 80 (7:24 No50) | |

| Number of spindle speed step | 22 | |

| Range of spindle speed | r/min | 4-800 |

| Range of facing head speed | r/min | 4-200 |

| Facing head diameter | mm | 750 |

| Number of facing head speed step | 18 | |

| Worktable size (L×W) | mm | 1600x1400 |

| Max. load of worktable | kg | 8000 |

| X axis traverse | mm | 2000 |

| Y axis traverse | mm | 1800 |

| Z axis traverse | mm | 1500 |

| W axis traverse (spindle travel) | mm | 900 |

| U axis traverse (Facing spindle travel) | mm | 250 |

| B axis worktable rotary | 360° | |

| Rapid speed (X/Y/Z/W) | Mm/min | 2500 |

| Measurement system reading precision(X/Y/Z) | mm | 0.005 |

| B-axis measurement system reading precision | 0.001 | |

| Power of main motor | kw | 15 |

2. General Introduction of TPX-series Boring Mill

1) General Information

The horizontal boring mill TPX series of our company is the finish machining equipment in the universal lathe machine. It is suitable for such operation as drilling, counter-boring, boring, reaming, spot-facing, tapping and milling etc. Also the horizontal boring and milling machine type is equipped with fixed facing head on which radial facing slide can be radically feed consequently to enable the machine to undertake boring of large-diameter hole, external cutting ,end face turning and recessing, etc.

The lathe machine is composed of bed, front column, headstock, cross and longitudinal saddle, worktable, back column and balance weight pulley etc. Their motions are the headstock moves vertically along the column's guideway, the worktable can move transversely and longitudinally on the bed, and the worktable can rotate.

2) Characteristics of TPX-series

A.The speed change of main motion and feed motion of the machine are all adopted hydraulic pre-selection centralized control which operation is simple and convenient. The indicator lamps are lighted up to give the signal during the course of speed and feed changing.

B.The motion distribution of longitudinal, cross travel and rotation of moving units of the machine such as headstock and worktable, clamping and unclamping of moving units are provided with automatic electrical hydraulic interlocking devices, this makes the machine with high automation.

C.The vertical coordinate(headstock lifting direction)and cross coordinate(worktable transverse movement)and longitudinal coordinate(worktable longitudinal movement, supplied according to the custom's requirement)are provided with new typeDigital Unit with memory function, which makes the machine with complete function and high accuracy.

D. Main parts of the machine such as bed, front column and guideways of longitudinal saddle are all adopted electric-contract surface heating self-cooling harden, which bring high stiffness of the guideways and extend the using life of the machine.

E. The horizontal guideway surface of the machine is provided with all pull-board type dust-proof.

F. Electric-hydraulic interlocking device will be fixed between the moving units and when a moving unit is moving, the other moving units will be clamped automatically (except spindle, radial facing slide).

G.In the headstock and rapid traverse gearbox, safety clutches are installed to prevent the machine from overload.

H. Electric-control system of machine adopts programmable controller with high reliability.

3) Transmission systems of the machine

A. Main transmission system

The rotation movement of boring spindle are driven by AC motor type Y132M-4-B5 through shaft coupling via the gears on shaft1,2,3,and 4, 5 to shaft 6 (boring spindle).There are four groups of sliding gears in this main transmission system,which is pushed via rotary valve controlling main transmission by four main speed change oil cylinder mounted in the headstock and enable them to locate in different position and enable the spindle to obtain 22 step speed change.The power from shaft is transmitted through shaft to the facing head,enable it to obtain 18 steps speed.

B. Feed motion

The feed motion of all moving units of this machine is feeding per spindle revolution(e.g.traverse rate of spindle,headstock,table per spindle revolution).The power of various moving units comes from shaft driven by main driven motor.It can be transmitted through gears of speed-change device to shaft (the feed safety mechanism).After that the motion will be transmitted further through the forward and reverse mechanism, to the feed shaft,then to the lead-screw or gear racks of various moving units,enable the spindle,headstock,cross & longitudinal saddles to obtain each 18 steps feed rates at low and high gear respectively.

The feed motion of the radial slide on the facing head comes from feed shaft through differential mechnism to worm racks,enable it to obtain 18 kinds of feed rates.

C. Rapid transmission system

The rapid moving of the spindle,headstock,cross & longitudinal saddles of the machine,the rapid rotation of the rotary worktable and rapid transmission of the radial slide on the facing head are driven by AC motor type Y100LA-4B5 mounted at the right side of the bed.Power from the motor is transmitted from shafts coupling and friction clutch to each moving units respectively,enable the spindle,headstock,cross & longitudinal saddles and the radial slide on the facing head to obtain the rapid moving speed 2500mm/min,the rapid rotation of the worktable is 1r/min.

4) Hydraulic system of the machine

The hydraulic system of this kind of machine is composed of two parts: One is in the tail bracket and upper and inner part of headstock which is used for spindle speed change and feed speed change and headstock internal lubrication. Another is in the inner part of longitudinal saddle of the machine, which is used for the transverse of headstock, longitudinal & cross movement and rotation of worktable Hydraulic system of main transmission,feed speed change and internal lubrication of headstock

3. General Terms:

3.1Payment terms:30% of the whole contact value as down payment by T/T.The last 60% of the wholecontact value should be paid byT/T before shipment after the final testing and inspection.

3.2 Delivery time:120-140days from the date we received the advance payment.

3.3Warranty and after sale service

3.3.1, Warranty period: one year after final installation, during the warranty period, all the daily damage parts will be provided freely by the manufactory.

3.3.2, Out of warranty period, the factory will still supply the support for the whole life of the machine, including technical advice, spare parts, labor, after sales service, and so on. But the factory will just take the necessary cost.

4. Pictures:

4.1 Pictures of horizontal boring machine:

4.2 Pictures of Loading:

4.3 Pictures of machine commissioning:

4.4 Pictures of our company:

| Packaging Detail:Dismantled into fumigated wood cases, loaded into containers. |

| Delivery Detail:2-3 months |