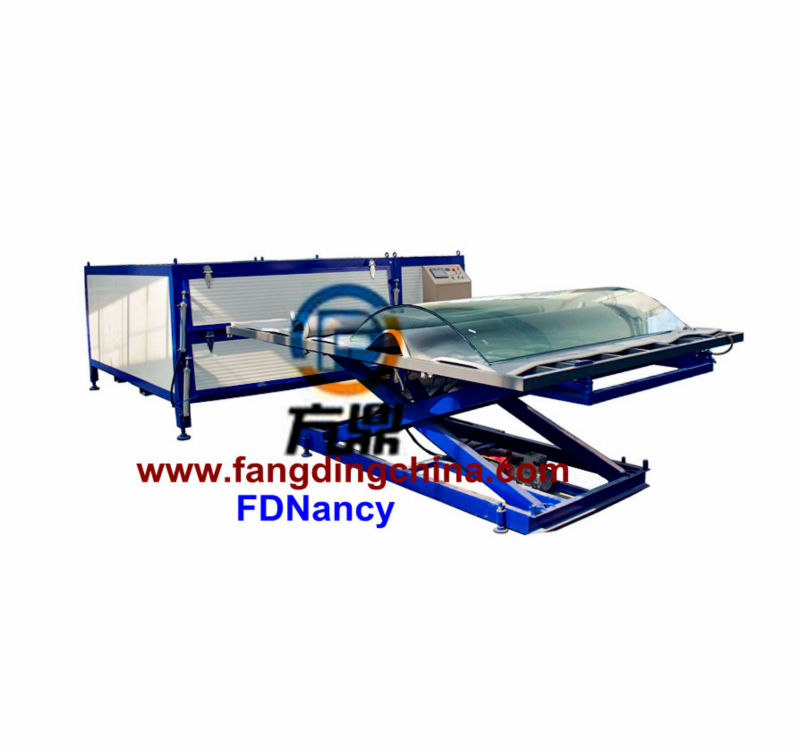

Top grade TPU/New PVB/EVA safety laminated glass furnace

TPU/New PVB/EVA safety laminated glass furnace, 1. Top grade, 2. Manufacturer with rich experience, 3. Energy saving - details see: https://www.machineto.com/top-grade-tpu-new-pvb-eva-safety-laminated-glass-furnace-10360092

| Place of Origin:Shandong China (Mainland) | Brand Name:Fangding | Model Number:FD-J-2-4L | Condition:New |

| After-sales Service Provided:Engineers available to service machinery overseas | Layer:4 |

Top grade TPU/New PVB/EVA safety laminated glass furnace

1) Our safety laminated glass furnace is the only one which could adopt TPU/NEW PVB/EVA film to produce all kinds of laminated glass, such as: architectural laminated glass, bullet-proof laminated glass, tempered laminated glass, arc/bending laminated glass, pattern laminated glass, art laminated glass, PDLC laminated glass, windshield, etc.

2) It can be used to produce true flower laminated glass, tempered laminated glass, and only we can promise you 99% production yield. It also can be used to produce bending laminated glass in one step.

3) Energy saving. It adopts patent heating system. It uses heating wire and turbo blower to heat. Hot air circulation and the enforced convection make the temperature go up fast in the furnace. It will save over 50% energy for you.

4) Our furnace adopts PLC. All the programs can be completed automatically. The heating time and temperature are adjusted according to the glass thickness. It uses the latest technology - special parts to extend the machine's service life.

5) The new safety laminated glass furnace adopts new insulation interlayer which is envirenment friendly. And it can insure the machine's excellent warm-keeping performance and durablity.

6)Vacuum systerm. Double vacuum pumps will make the vacuum effect stable and fast. It can work 24-hour all day, and make sure there are no air bubble in the laminated glass.

The silicone bags, as you know, are imported from USA. It features good seal, high temperature proof, high tear resistance, anti-aging and could be used at least 4 years.

7) Lifting platform adopts photoelectric controller which allows accurate tray alignment in correspondence with respective floor, whether when you place the tray into the furnace or pull it out. Easy and convenient, it will save your labor and cost.

8) We promise that we will offer you the best after sales service for ever. If there are any problems troubled you when you producing laminated glass, please feel free to let us know. We will solve the problems for you in first time.

Technical parameters:

| Electric Power | (3-phase AC 220-380V)/58KW |

Processing Glass Size | Max: 2300*3600mm / Min: 100*100mm |

| Arch Height: 400mm (Max) | |

| Glass Thickness: 36mm (Max) | |

Efficiency | 50-90 Minutes |

| 99m² | |

| Exterior Dimension | 3600*4200*1600mm |

| Working Temperature | 90-140°C |

| Net Weight | 4090kg |

Application:

1. Curtain wall, skylight, balcony gardrail, awning, stair rail, etc

2. Bank, hospital, goverment building, store, etc

3. KTV, pub, hotel, beauty salon.etc

4. Villa, high-grade houses

5. Interior partition, decoration, etc

6. Kitchen and bathroom decoration, etc

7. Furnature

8. Auto windshield, etc

Our warehouse:

| Packaging Detail:Sea worthy export packaging |

| Delivery Detail:25 days after prepayment |