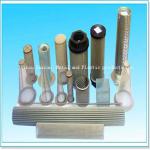

TM vacuum ceramic filter

| Place of Origin:Zhejiang China (Mainland) | Brand Name:HEHUI | Model Number:TM/TH/TC | After-sales Service Provided:Engineers available to service machinery overseas |

| Material:steel/Ceramic | Function:solid-liquid separation | Structure:circular disc |

Disc vacuum filter

Equipment introduce:The filter is solid-liquid separation equipment with high efficiency and energy-saving.It has advanced technology and contact construction,it is high-tech products which integrate electromachinery,millipore ceramic filter plate,ultrasonic washing and automatization control into one. Depending on vacuum absorbing and capillary effect to come true separation of solid and liquid. It adopts multi-aperture ceramic filter plate of non-watertight and airtight as filtering medium,and vacuum degree can get -0.096~-0.097 Mpa to make sure good dehydration effect. It can widely used in mines, metallurgy,chemistry, food, coal, medicine and environment protection, th e filtering precision is 0.2μm~3mm, especially used in sand material solid-liquid separation . It has good effect to glutinous material through adjusting slime performance, energy-saving is one one tenth to common vacuum filter.

Working principle

Slime Absorbing Zone: Filter plate immersed in the slime while in operation produces a surface absorption of filter cake,with the action of capillarity and integrated with vacuum pressure. Filtrate enters distributing valve and drainage tank through filter plate.

Spraying Zone: Filter cake comes out from slime hopper receiving spray washing.

Draying Zone: Continuous dehydration for filter cake is conducted with the action of high vacuum force.

Discharging Zone:Scraper will automaticly discharge materials once entering the vacuum-free condition.

Back Flushing: Service water or filtrate enters the ceramic plate through distributing valve and cleaning the blocked minihole entoectad. Cleaning with ultrasonic and low density acid after ceramic plate is used for one period to maintain the efficient service life of ceramic plate.

Features

1.High vacuum degree ( vacuum degree -0.09~-0.098MPa ), low moisture of cake.

2.High filtration precision, solid content of filtrate<50ppm, which can be recyle used in the system.

3.Energy saving can reach 90%,low energy consume, low running cost.

4.Filter cake cleaning system is added, which is fit for the material needs to be washed.

5.PLC and computer integrate with automatic valve control, high degree of automation reduces labor intensity.

6.Compact structure requires a smaller floor space and offers convenient maintenance.

7.Advanced drainage system ensures application in any running conditions.

| TM series of ceramic vacuum filter Selection Table | |||||||||||||||||

| Type | TM-1 | TM-4 | TM-6 | TM-9 | TM-12 | TM-15 | TM-21 | TM-24 | TM-27 | TM-30 | TM-36 | TM-45 | TM-60 | TM-80 | TM-100 | TM-120 | |

| parameter | |||||||||||||||||

| Filter disc (circle) | 1 | 2 | 2 | 3 | 4 | 5 | 7 | 8 | 9 | 10 | 12 | 15 | 15 | 20 | 20 | 24 | |

| Filter plate number (block) | 12 | 24 | 24 | 36 | 48 | 60 | 84 | 96 | 108 | 120 | 144 | 180 | 180 | 240 | 240 | 288 | |

| Volume (M3) | 0.2 | 1 | 1.2 | 1.7 | 2.2 | 2.7 | 4 | 4.5 | 5 | 5.5 | 7 | 8.5 | 12.5 | 16.2 | 18.5 | 22 | |

| Installed(KW) | 3.5 | 7 | 7 | 9 | 11 | 11.5 | 13.5 | 16.5 | 17 | 17.5 | 23 | 25 | 33 | 40 | 53 | 60 | |

| Equipment weight (T) | 1 | 2 | 3 | 3.5 | 4 | 4.5 | 9 | 9.5 | 10 | 10.5 | 11.5 | 13 | 17 | 19 | 25 | 30 | |

| Running power(KW) | 2 | 3 | 6 | 7 | 7.5 | 8 | 9 | 10.5 | 11 | 11.5 | 16 | 19 | 22 | 24 | 35 | 40 | |

| Host length (M) | 1.6 | 2.4 | 2.4 | 2.7 | 3 | 3.3 | 4.6 | 4.9 | 5.2 | 5.5 | 6.6 | 7.5 | 7.5 | 9 | 11 | 12.2 | |

| Host Width (M) | 1.4 | 2.5 | 2.9 | 2.9 | 2.9 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.3 | 3.3 | 3.6 | 3.6 | |

| Host height (M) | 1.5 | 2.1 | 2.5 | 2.5 | 2.5 | 2.5 | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | 3 | 3 | 3.3 | 3.3 | |

| Packaging Detail:general machinery equipment packing , strong enough to withstand rough handling, well protected against dampness, moisture, rust and shock. |

| Delivery Detail:60 days |