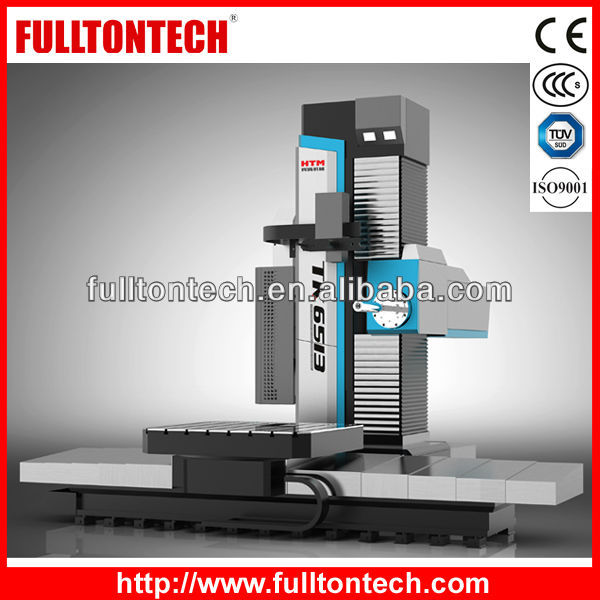

TK6916 Boring Machine

| Condition:New | CNC or Not:CNC | Production Capacity:High | Place of Origin:Liaoning China (Mainland) |

| Brand Name:FULLTONTECH | Model Number:TK6916 | Voltage:According to clients site voltage | Power(W):30 Kw |

| Dimension(L*W*H):9.4x4.4x7.5 | Weight:150TONS | Certification:ISO9001:2008; CE Certificate | After-sales Service Provided:Engineers available to service machinery overseas |

| Type:Boring Machine | Material:High grade cast iron | Transportation method:Seaway or railway | Guarantee:One year guarantee |

| Functions:Boring; milling | Colour:Blue and grey | CNC System:Digital display or CNC system | Packing:Fumigated wood box |

| payment term:TT with down payemt; 100% irrevocable LC at sight | Production period:3-4 months |

CNC Floor Type Boring Machine

2. Pictures

2.1 Pictures of boring machine details:

2.2 Pictures of boring machine packing and loading:

2.3 Pictures of boring machine inspection:

2.4 Pictures of other product from our product line:

More details of this boring mill

1,Brief introduction

1.1. TK6916 Floor Type Boring and Milling Machine is a machine equipped with advanced techniques such as mechanics, electrics and hydraulics. Many key techniques are adopted: Hydrostatic guideway (constant flow), No back-lash rack-pinion drive system, ram feed auto compensation, etc. The machine is equipped with advanced CNC control system Siemens 840D or Fanuc 18i MB with FAGOR/HEIDENHAIN position sensor system, to make the machine in close-loop. All these well know and advance equipment make the machine with high rigidity, great efficient, easy operating and maintenance.

1.2. To assure the accuracy and big torque at the same time, we improve the structure of ram to add another 4 sets (totally 8 piece INA bearings) to support.

1.3 The machine has many self independent lubrication systems for different parts, especially for the boring head, to assure the effect of lubrication for the boring head.

1.4 Except the casting of the machine, all the components are imported from German, Switzerland and America.

1.5. The machine can complete boring, milling, drilling, reaming and tapping etc. machining procedures with once clamping. Optional equipped with right angle milling head, universal milling head, rotary table and other optional accessories, it can do heptahedron machining.

2.Feature of the structure

2.1Spindle

The spindle is composed of boring spindle and milling spindle. The bearing of the spindle adopts the imported group bearings of high speed, superior rigidity and high precision, and has the feature of heavy load and long-lasting precision.

2.2The main configuration boring and milling head

Spindle and boring axis are mounted inside the ram

The spindle can perform horizontal slip inside the boring axis.

The square ram is mounted inside the headstock.

The square ram is the form of vertical big size section so as to increase the rigidity in longitudinal.

The headstock adopts the configuration of whole containing; the ram is contained inside the headstock and further increase the complete rigidity of the ram and vails the machine for big force machining.

2.3Transmissionsystem

The main drive motor of this machine is DC motor with hydraulic two steps speed change, speed changing is controlled by CNC system, which could realized the turning speed form 2to 800rpm(Option:2000rpm), during this speed range, the speed changing is stepless. The feeding system totally has four main parts:

1, Column horizontal feeding(X axis),

2, headstock vertical feeding (Y axis),

3, Boring spindle feeding (Z axis)

4, Ram axial feeding (W axis)

2.4Hydraulic and lubrication system

Machine adopts two sets of hydraulic system. One system supply oil to the brake of ram and spindle box, spindle speed regulating, and the lubrication of spindle, milling head and ram. The oil tank is located in the bottom of spindle box. Second hydraulic system take care of the brake of column and hydrostatic & lubrication oil for column. Oil tank is located on the machine base.

Both systems equipped with oil cooling and temperature auto-control device, to guarantee the machine working in good condition. There are several temperature sensors which connect with oil temperature auto-control device, mounted on spindle, column and oil tank to control temperature rising which bring about thermal deformation and machining accuracy changing.

Machine could work in low temperature condition, which benefit from heating device in oil tank and heat insulation for uncovered oil pipe.Machine has Oil temperature alarm device and low level alarm.

2.5 Machine CNC axes

Machine total have 4 axes (If choose the rotary table, will total has 7 axes), Z axis is semi closed loop control system, and the other axes are all closed loop control system.

W-axis: Ram axial moving in the Headstock Z-axis: Spindle axial moving in the Ram Y-axis: Headstock vertical moving along the Column X-axis: Column longitudinal moving on the Bed.

B-axis: The rotary axis of rotary table

V-axis: The longitudinal moving of rotary table

A-axis:Spindle and ram extend out of headstock. Actually A axis is kind of compensation, because if the spindle and ram extend too long outside, it have to be bending. The CNC system could calculate the length of spindle or ram extend out, and will make the compensation in the CNC system.

2.6Working Condition

Power supply:3PH, 380V, 50HZ±1HZ (can be optional supply according to customer’s local power source)

Circumstances Temperature: 0~45°C

Relative humidity:≤80%

Total power:about 190Kw

| Packaging Detail:Dismantled into fumigated wood box, loaded into containers, suitable for seaway and railway transportation. |

| Delivery Detail:2-3 months |