Titanium MF vacuum coating machine

| Condition:New | Type:Coating Production Line,Machine | Substrate:metal | Coating:Vacuum Coating |

| Place of Origin:Zhejiang China (Mainland) | Brand Name:Chicheng | Model Number:CCZK-1300I | Voltage:380v |

| Power(W):42kw | Dimension(L*W*H):1300X1300mm | Weight:6500kg | Certification:Certified ISO9001 |

| Warranty:1 year | After-sales Service Provided:Engineers available to service machinery overseas | color:blue&yellow,white | size:1300mm.times.1300mm |

| angle:front view |

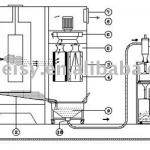

1.Titanium MF vacuum coating machine is a ion coating machine of efficiency, harmless and pollution-free. It has the features of fast deposition rate , great ionization rate, big ion energy,easy operation, low cost, large productive capacity, etc.

2. This Ceramic tiles vacuum coating machine:The principle of the electric arc is intergrating cold cathode arc discharge self-sustained light unite pulse technique and magnetron sputtering technology, thinning the particles to improve the properties of the film. It can coat on the surface of the metal as well as nonmetal.

3. Pvd vacuum coating machine: It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper , and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film, and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

This machine is extensively used in the fields of ultra-hard coating about the tools and mould, decorative coating about car wheels, ceramics, golf, watches making, hotel product, sanitary ware, luminaires, optical frame, hardware, etc .

Ion coating equipment main model and parameters | ||||||

| Model | CZ-800 | CZ-1000 | CZ-1300 | CZ-1600 | CZ-1800 | CZ-2200 |

| Vacuum chamber | 800*800 | 1000*1100 | 1300*1300 | 1600*1800 | 1800*3000 | 2200*4000 |

| Arc target amount | 4 or 6pcs | 6 or 8pcs | 12 or 14pcs | 16 or 18pcs | 30 or 32pcs | 38 or 40pcs |

| bias supply | 15KW/pcs | 20KW/ pcs | 42KW/ pcs | 50KW/pcs | 60KW/pcs | 80KW/ pcs |

| Total power | 30KW | 40KW | 60KW | 80KW | 125KW | 195KW |

| Power supply type | Arc power source, filament power,pulsed bias power supply | |||||

| Chamber structure | Vertical & front door, rear pumping system, double water-cooling chamber | |||||

| Chamber material | Stainless steel | |||||

| Ultimate vacuum | 6.0×10-4Pa | |||||

| Pump-down time | 8.0×10-3Pa≤15min | |||||

| Vacuum system | Diffusion pump or molecular pump +Roots pump +Mechanical pump+ holding pump(can be allocated by customer’s requests) | |||||

| Workpiece system | Rotation of the planet forms, frequency regulation(adjusting rotation speed) | |||||

| Workpiece heating temperature | From room temperature to 450°C, adjustable control(PID temperature control) | |||||

| Process gas | 3-channel or 4-way process gas flow control and display system, matching automatic refueling systems | |||||

| Water-cooling system | Water circulation cooling system, and water tower or industrial chiller or deep-cooling system(supply by customer) | |||||

| Control method | Manual/automatic all-in-one,touch screen,PLC or computer operation | |||||

| Alarming and protection | Alarming for short of water, overcurrent, overvoltage and circuit break, etc of pump and target, and carry out protections and electrical interlocking functions | |||||

| Other technical parameters | Water pressure≥0.2MPa,water temperature≤25°C,air pressure0.5-0.8MPa | |||||

| Remarks | Configuration of coating equipment can be designed according to the requirement of the coated products | |||||

| Packaging Detail:Wooden case packing |

| Delivery Detail:About 30days after received customer's payment |