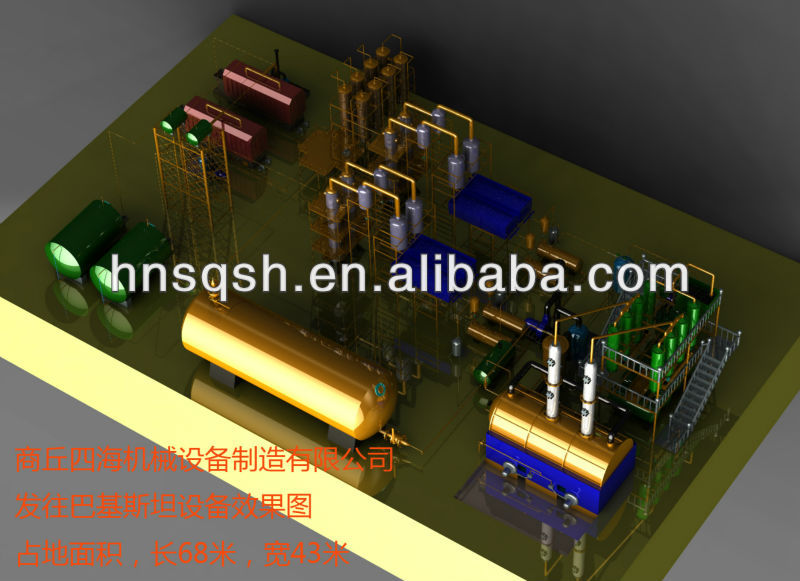

The Production Line for Recycling Waste Tire/Rubber/Plastic to Diesel Directly

| Condition:New | Type:Tire Machine,enveronment protection | Tire Machine Type:Tire Recycling Machine | Place of Origin:Henan China (Mainland) |

| Brand Name:Sihai | Model Number:LJ ZL | Voltage:380V | Power(W):50KW |

| Dimension(L*W*H):2600*6600 | Weight:33KG | Certification:ISO9001:2008 ISO14001:2004 CE | Warranty:one year |

| After-sales Service Provided:Engineers available to service machinery overseas |

ROLYSIS PARTS :

Function:to recycle waste tyre /plastic into curde oil .

Price:

| Model No. | Capacity Per batch | Reactor Size Diameter with length | Reactor Thickness | Reactor Quality | Sea freight charge One complete set to | |

| Generation Four | 5ton | 2200mm*6600mm | 14mm | Q245R boiler steel | US$ for 2*40”HQ | |

| Generation Five | 5ton | 2200mm*6600mm | 14mm | Q245R boiler steel | US$ for 2*40”HQ | |

| Generation Four | 10ton | 2600mm*6600mm | 16mm | Q245R boiler steel | US$ for 1*40”FR +1*40”HQ | |

| Generation five | 10ton | 2600mm*6600mm | 16mm | Q245R boiler steel | US$ for 1*40”FR +1*40”HQ |

DISTILLATION PARTS:

Function:further process crude oil into diesel and gasoline.

Price:

| Model No. | CapacityPer 24hours | Reactor Size Diameter with length | Reactor Thickness | Reactor Quality | Sea freight charge One complete set to | |

| Generation Five | 10ton | 1600mm*4000mm | 16mm | Q245R boiler steel | US$ for 1*40”HQ |

1.Energy safe 30%

after 8 years experience ,we had changed the outside cover and foundation for inner reactor together ,which have better hot reservation ,which can short the running time for hearting 3-4 hours at least .reactor picture as below :

Easy Control and operation

the new technology ,which with auto feeding and discharging .even for pyrolysis and distillation which connected by vaccum system ,it easy to control and operation ,only need two or three labor for the whole process .

safety ensured

the safety problem was the first important thing we need to ensure during the past 8 years we do in waste recycling industry .if without safety ,then we have nothing .so for the new generation ,we had install addtional two safety points to ensure the whole process was safety except the gas empty valve ,auto alarm system .

Frist one :auto explosion plate in reactor door when pressure over 0.04mpa.when it give us another insurance for the full door in biggest reactor 2800*6600 .

Second safety :auto open valve when it over pressure in gas seperator .during the process ,if there have anything innormal ,this valve will be outo open and relife the pressure and hot energy .in the same time ,the alarm system also will give us a bigger notice .

The outpout according to difference raw mateiral :

| Item | raw mateiral | Output |

Tyres | Steel wire tyre | 40%--55% |

| Nylon tyre | 40% | |

| Bicycle tyre | 35% | |

Paper pulp | Coarse material | ≈15% |

| Water washing material | 23%-26% | |

| PE material | ≈70% | |

Cable skin | PE cable skin | ≈85% |

| PVC cable skin | ≈25% | |

| Pure rubber cable skin | ≈35% | |

| Telephone wire | ≈50% | |

Life Garbage | Pure plastic bag | ≈50% |

| Coarse material with water | ≈15% | |

Weaves & Handbags | ≈60% | |

shoes | Sports shoe’s sole | 27%-33% |

| Black rubber | ≈35% | |

| Gum outsole | ≈45% | |

Others | Common rubber pipe | ≈30% |

| Carpets | ≈35% | |

| Aluminum foil | ≈30% | |

| Car glass bead | ≈50% | |

| PP Beverage bottle | ≈50% | |

The Related Certificate

The final diesel after process:

| Packaging Detail:normal package |

| Delivery Detail:40days after advanced payment |