The lowest price sand making production line

| Condition:New | Production Capacity:above 85% | Place of Origin:Henan China (Mainland) | Brand Name:XKJ |

| Voltage:380V | Certification:ISO9001:2008,CE | Warranty:One year except wearing parts | After-sales Service Provided:Engineers available to service machinery overseas |

| Model Number:Standard | Type:Sand making production line | Color:Any color is available | manufacture standard:accord with industrial standard |

| Guarantee period:the whole using life | Quality:reliable | workmanship:Advanced | performance:stable |

| operation:easy | quality control:go through five checks |

Application of sand processing machine:

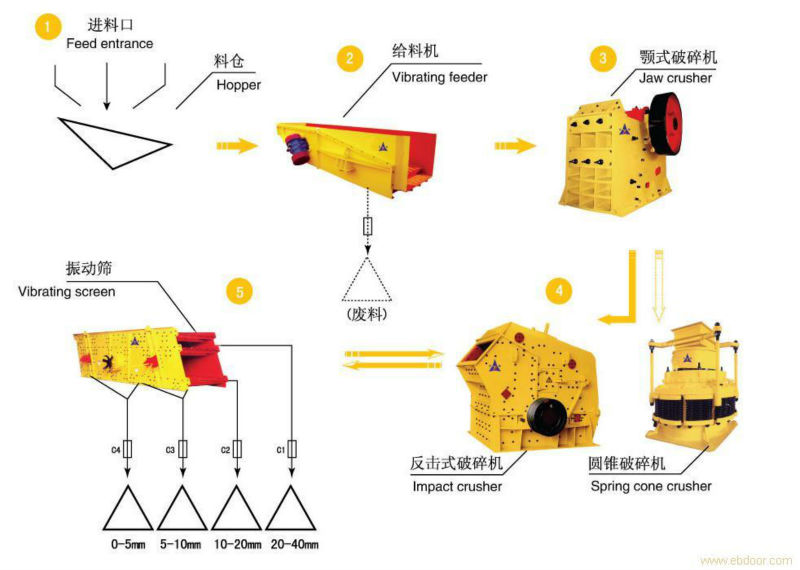

Our sand production line mainly consists of vibrating feeder, jaw crusher, sand making machine, vibrating screen, sand washing machine, belt conveyor, electric control panel, etc. Our sand production line is taking the leading role in the sand making industry. Sand production line can crush hard limestone, granite, basalt, river stone, etc, and widely used in hydropower, building material, highway, city construction, etc.

Brief Introduction of sand processing machine:

Large stone is transported to jaw crusher via vibrating feeder for primary crushing. Then crusher material is transported to sand making machine. Then the stone are screened out into several different types with a vibrating screen. Stone with satisfied size is transported to sand washing machine, then it will be final product, while overlarge stone is returned back to sand making machine for re-crushing.

Process of sand processing machine:

The raw material is transferred to jaw crusher for primary crushing by vibrating feeder, then the crushed materials are transferred to sand-making machine through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen. The materials with suitable size will be transferred to sand washing machine, after being washed, then clean final products will be discharged. The others with unsuitable size will be screened from vibrating screen, and then will be transferred to sand-making machine, this form a closed circuit manifold cycles.

Sizes of final products will be according to our customers’ requirements.

If you interesting in our products, pls give us the following information:

1.which kind of raw material?

2.the max feeding size

3.the capactity per hour

4.the final product you want to get

| Packaging Detail:Export standard container 20GP OR 40GP,40HQ,FR container, In bulk, the spare parts in wooden case |

| Delivery Detail:25 days after receiving your deposit |