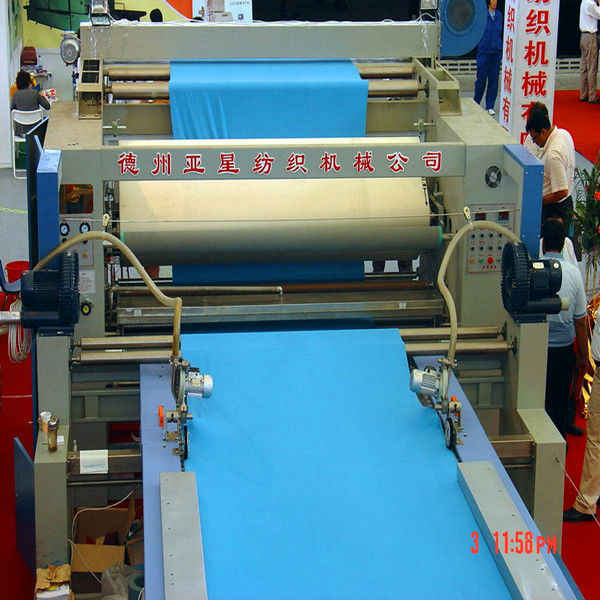

textile open width compactor

| Condition:New | Automatic Grade:Automatic | Place of Origin:Shandong China (Mainland) | Brand Name:Asia Star |

| Model Number:YXLS2400 | Voltage:220v | Power(W):100kw | Dimension(L*W*H):40000mmx5100mmx2000mm |

| Weight:15tons | Certification:chinese | Warranty:one year | After-sales Service Provided:Engineers available to service machinery overseas |

| gray:blue |

Usage of the machine:

This open width compactor mahcine is suitable for the pre-shrinking of open width natural fiber such as cotton, grass ,and wool. the water shrinkage of the fabrics is less than 5%.

Main technical parameters:

Chain working pattern : chains circulation horizontal rotary

Compacting pattern : thickness 20-21mmNomex felt

Chains pattern: pitch 60mm,stainless steel chains.

Rail pattern stainless steel rail,graphite strip,non oil lubrication

Machine standard power: 380V(±5%)50Hz3PH

Control power: 220V,24V

Applicable steam specification: 3-6Kg/cm²saturated steam

Steam comsumption : 100~150kg/hour

Applicable compressed air specification: 0.3-0.6Mpa compressed airwithout moisture

Maximum temperature of the dryer cylinder: 190°C

Applicable heat sourch A. Circulation thermal oil

B. Electric heated thermal oil

C. Steam

Circulation oil consumption: 30000-40000Kcal/ H(0.125-0.2GJ)

Electric heated thermal oil consumption: 25-54KW

Steam roller consumption: 100-150Kg/H

Main chain driven pattern:right and left chains drive seperately

Felt maximum working width:2600mm

Pin plate maximum working width:2800mm

Width control pattern: front and back drive seperately

Machincial speed : 5~35m/min

Power of some parts: gluming,cutting,sucking device 6.74 KW(optional)

Pneumatic edge spreader 3KW

Driven device 25 KW

Machine dimension(Max) L=15000 W=2570+working width H=2800

Machine weight: about 12tons

Machine colour: jewelry blue + Crystal White

Machine advantages:

Infra-red centering infeed device, correct the fabrics movement path automatically(shanghai brand)

Equip weft correct adjusting roller, cooperate with the stenter frame pin plate, with a different speed to correct the fabrics weft.

Pneumatic edge spreader(teeth spreader is optional) to flat the curled edges.

Far infra-red auto edge detector and tracing system made in Shanghai, which can guarantee the fabrics pin on correctly, the width of the pin can be controlled in minimum .

The wool brush wheel overfeed and pin on, right side and left side are driven by the separately motor, controlled by the inverter, overfeeding rate is -20%---+30%.

The chain copies Hercules of Germany.

The right and left stenting frames are driven by the separately motor, can movement with the little different speed, cooperate with the weft straighter to correct the weft.

In front of the stenter frame and felt compacting unit, equip two steaming box made of stainless steel, the stenter frame steaming box equips air curtain in front side to block off the steam dissipation, which can guarantee the edge detector works normally(not disturb by the steam).

Two pieces of thicken felt(20mm),the felt is used to compacting and setting, especially for open width fabrics,material is Du pont Nomex.

Drying cylinder Heated by electric thermal oil (steam is optional), intelligent control. Temperature tolerance is +_3°C.

The fabrics output by plaiting mode.

Equip synchrocontrol devices, can harmonize the proportional speeds of each units automatically.

Adjust the speed of the machine by inverter, HIM operation system. PLC programme controlled.

Machine drawing:

| Packaging Detail:plastic |

| Delivery Detail:30days |