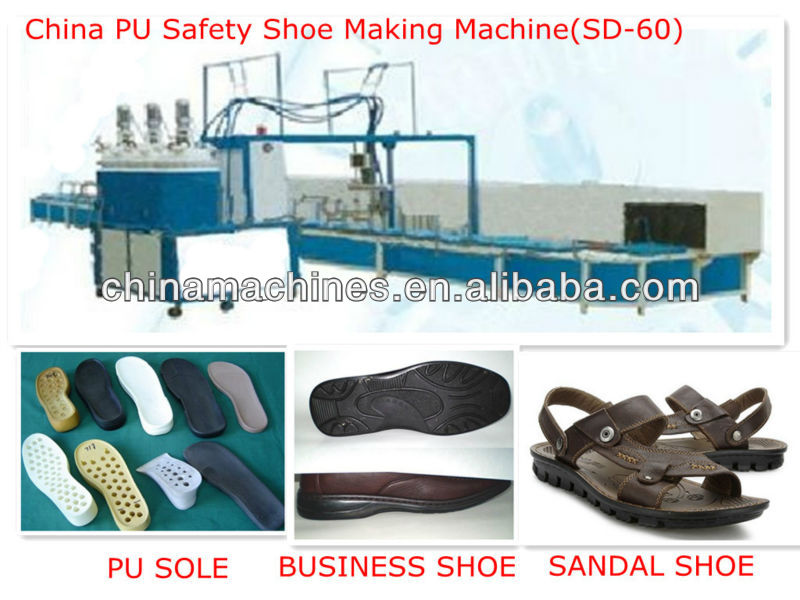

Taiwan 46 / 60 / 70 Stations PU pouring shoe making machine

| Place of Origin:Zhejiang China (Mainland) | Brand Name:SUNDIEA | Model Number:SD-60 | After-sales Service Provided:Overseas service center available |

| COLOR:2 COLOR | MATERIAL NAME:PU RESIN | ORIGIN:CHINA | CONVEYOR:20,40, 60, 80,100STATIONS |

| PRODUCTIVITY:15000PAIR/DAY | CERTIFICATION:CE,ISO | AUTO/SEMI:SEMI AUTO | WORKER:10WORKER |

46 / 60 / 70 Stations PU pouring shoe making machine

Double color double density polyurethane pouring molding machine is specialized polyurethane sole molding and upper-link molding. Polyurethane pouring molding machine is one set of pouring molding product equipment composed by Polyurethane pouring machine main machine and molding conveyor assistant machine

SUMMARY

The all sizes and specifications of soles and upper connection moulds can be installed on the multi-station support.The injectors for the polyurethane foaming machine or polyurethaneinjiction moulding machine will continually inject the liquid mixed polyurethane when forming assemble line runs at an average speed. The liquid mixed polyurethane form the moulds will be made into all sizes of slippers or soles.The polyurethane foaming machine or polyure thane injection moulding machine will continually inject the liquid mixed polyurethane in production ,featuring high production efficiency compared to the rotary polyurethane injection moulding machine.

Main technical parameters

Number of stations :60-100stations

Adjustable speed scope:m/mim 0-120

Adjustable bemp.scope inside the oven channel:80 °C room temp.

Temperature difference inside the oven channel:less than 8

Outlood and construction schematic diagram

Technical Parameters for the Assemble Line

| Model | Name of Article | Dimension | Illustration | (KW) |

| 360 | Upper Connecting-Moulding Assembly Line 60 | L ×W × H ( m ) 18.95 × 1.98 × 1.28 | Oli Heating Electric Heating | 627 |

| 370 | Upper Connecting-Moulding Assembly Line 60 | L × W × H ( m ) 21.95 × 1.98 × 1.28 | Oli Heating Electric Heating | 636.6 |

| 380 | Upper Connecting-Moulding Assembly Line 60 | L × W × H ( m ) 24.95 × 1.98 × 1.28 | Oli Heating Electric Heating | 636.6 |

| 372 | Upper Connecting-Moulding Assembly Line 72 | L ×W × H ( m )18.95 × 1.98 × 1.28 | Oli Heating Electric Heating | 636.6 |

| 384 | Upper Connecting-Moulding Assembly Line | L × W ×H ( m ) 21.95 × 1.98 × 1.28 | Oli Heating Electric Heating | 636.6 |

| 396 | Upper Connecting-Moulding Assembly Line 96 | L × W × H ( m ) 24.95 × 1.98 × 1.28 | Oli Heating Electric Heating | 636.6 |

Two color and three color available

It 's used for making safety shoe, leisure shoe, leather shoe/sole, etc.

1, On the turning circularity molding line which is mould-frame of horizontal multi-position, there are all kinds of specification and model moulds of sole and upper-link molding. When molding line runs equably and circularly, the pouring head of polyurethane foame machine or polyurethane pouring molding two purpose machine pour mix material liquid into the moulds continuously, after the material liquid processed molding in the moulds, which make many kinds of eligible molding shoes or soles.

2, Equipments productivity

polyurethane foam machine matches with sole molding molding line(60 position or more), we produce polyurethane soles by 50 shoe moulds, 10 hours one day and 8 circles/hour, as the rotating speed, it can yield 4000 pairs of soles per day.

3, Polyurethane foamed machine matches with sole upper-link molding production line(60 position), we are produce 10 hours one day and 8 circles/hour, as the rotating speed, it can yield 1200 pairs of soles per day.

4, Double color, double density polyurethane sole or upper-link molding shoe products, this techniques should be second pouring, so productivity will be decline

| Packaging Detail:Standards packing |

| Delivery Detail:15DAYS |