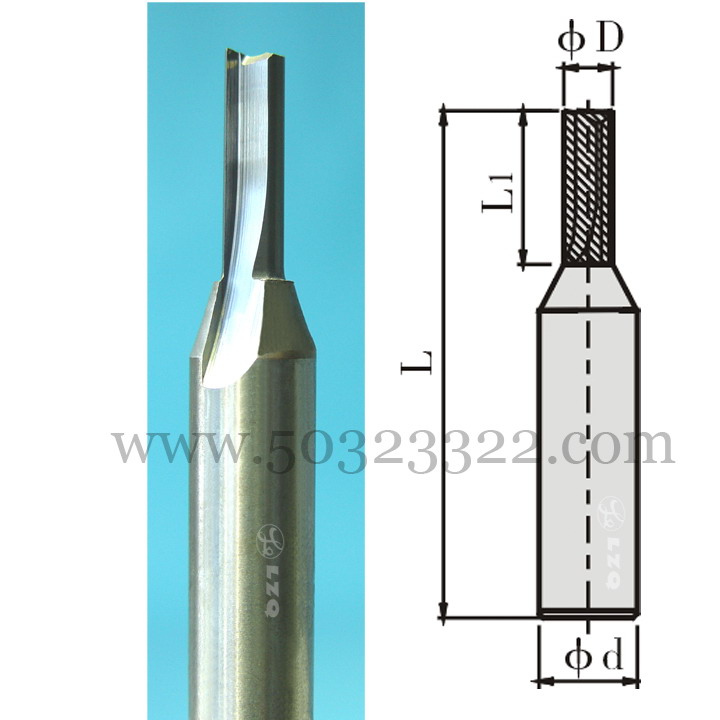

T.C.T Carpenter Tool

| Place of Origin:Shanghai China (Mainland) | Brand Name:LZQ |

Adopting advanced power high speed CNC grinder from Germany and Switzerland as well as high precision (3DX technology) grinding of high quality super micro-grain tungsten steel (quality carbide), it has perfect flute and size tolerance can up to ±0.001mm(±1μm) high. Cold-hard machining replacing grinding can improve precision, hard milling replacing grinding can improve efficiency.

Type of material K10/HRF10/MR11/MR12/PR40/PRA5/NRA61/PRA11/VRA201/ASP60C/SKH57A/SKH55A/VWA201/SKH4C(Stainless high speed steel)/VWA441/VWA431

High impact resistance diamond tungsten steel (for intermittent cutting)

High hardness quality carbide (for ultra high wear resistance) HRF10/NRB10Z

Tungsten steel meeting ISO standard (for general machining) MR11/PR40

High cobalt HSCo8 (skh59), ASP60C German standard

Type of flute: (standard and non-standard 1-flute~12-flute series mill): deep groove, round head, end angle R, hollow, oblique flute (tapered), long flute, for aluminum, copper application, chip-dividing groove (for rough mill application)

Mill diameter: (miniature) φ0.10mm---φ53.00mm (solid tungsten steel),

φ20.00mm--φ80.00mm (brazing)

Tolerance: (standard and non-standard) tolerance of flute diameter of diamond tungsten steel can be up to ±0.001mm (±1μm) high, and tolerance of holder diameter is more than h6.

Helical angle: 0°,25°,30°,35°,45°,50°,55°,60°

Cold-hard machining replacing grinding can improve precision, hard milling replacing grinding can improve efficiency.

(Non-coated diamond steel tooling for high hardness steel machining can replace TiALN coated super micro-grain tungsten steel, ceramics. After cutting, CBN tooling has excellent smoothness and lower tooling cost.)

We can produce special, compound, special-shaped, super-large/ super-thin/ super-long combined profiling series tooling according to requirements of drawings, samples, and dimension tolerance.

| Packaging Detail:custom |

| Delivery Detail:1-3weeks |