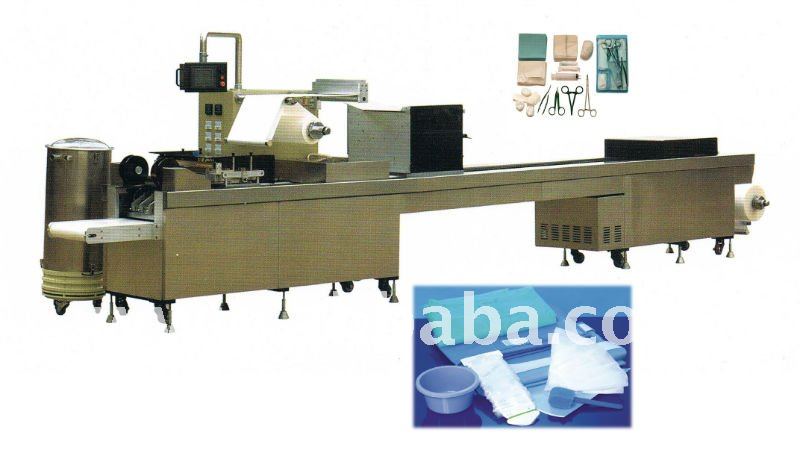

surgicals packs and kits packaging machine

| Type:Blister Packaging Machine | Condition:New | Application:Medical | Automatic Grade:Automatic |

| Driven Type:Energies: Electric, Pneumatic, Mechanical | Power:380V 50Hz | Place of Origin:Hong Kong | Brand Name:SP packaging |

| Model Number:WL-500W | Thermoforming module:Automatic | Filling module:Automatic | Sealing module:Automatic |

| Cutting module:Automatic | Printing module:Automatic | Packaging Material:Plastic | Packaging Type:Medical devices |

Hard or soft blister packaging machine

CE Blister packaging machines designed for packing medical devices in hard and soft blisters.

Trays customized according to products design and customer's requirements. Spares parts selected (preheating, thermoforming, transferring, printing, sealing, and cutting modules) according to packaging raw material selected.

Product examples packed in soft or hard blisters:syringes, dressing sets, infusion sets, dressing kits, dressing sets, surgical drapes…

Global information:

| Machine Type | Packaging machine |

| Reference | WL-500W |

| Packaging Type | Hard/Soft blisters (4 sides sealing) |

| Blister/Width | according to product design and customer's requirements |

| Film Type | PE, PVC, PET/PE, OPP, PS, Medical paper, aluminum foil, etc (spares parts and systems manufactured according to raw material) |

| Film Thickness (top&bottom) | Paper : 50 to 150µ Plastic film : 50 to 500µ |

| Remote control /screen | Touch screen panel (different languages available) |

| Software | Password security for operators and users |

| Maximum Speed | 20 cycles/minute (according to mould size) |

Blisters size (customized according to requirements) | |

| Minimum Length | 10mm |

| Maximum Length | 420mm |

| Minimum Width | 20mm |

| Maximum Width | 500mm |

| Minimum Depth | 5mm |

| Maximum Depth | 80mm (according to thikness of film) |

General information | |

| Total Length | 8 meters maximum |

| Total Width | 1.3 meters maximum |

| Total High | 2 meters maximum |

| Net Weight | 1.8 Ton maximum (according to spars and systems) |

| Compressed Air needed | 6 bars minimum |

| Air consumption | 250 liters/minute |

| Cooling system needed | Below 25°C, between 30 and 40 liters/hour (closed circuit) |

| Energy | 380 VAC, 50Hz |

| Power | Below 17KW |

Options (system) | |

| Option 1 | Vaccum pump |

| Option 2 | Waste edge collecting bucket |

| Option 3 | Ink or thermal transfer of flexography printing system |

| Option 4 | Water cooling system (closed circuit) |

Pack proposed:

- Feasibility studies,

- Process development and manufacturing,

- Export and installation,

- Trainings: using & global maintenance,

- Machine and packaging Validation according to ISO11607: 2006 + EN868-5: 2009 and others norms related,

- After sales services.

Machines already exported too: Bulgaria, Thailand, China, South Korea, Spain, Iran, Peru, France, Poland, Portugal, Tunisia and Turkish.

Contact us for details and quotes.

| Packaging Detail:Packaged in wood cases with inner protections |

| Delivery Detail:1 month |