Supply ISO and CE Certified Chromite Zirconium Magnetic Separation Process

| Condition:New | Type:Magnetic Separator | Production Capacity:10-280t/h | Place of Origin:Henan China (Mainland) |

| Brand Name:Hongxing | Model Number:CTB | Voltage:380v 50HZ can be adjusted according to requirements | Power(W):1.5-11KW |

| Dimension(L*W*H):as requested | Weight:it depends | Certification:ISO9001:2008,CE | Warranty:1 year |

| After-sales Service Provided:Engineers available to service machinery overseas | Application:iron ore separating | Shell diameter:600-1500mm | Shell length:1200-3000mm |

| Shell rotation speed:<34r/min | Feeding size:3-0mm | Processing capacity:10-280t/h | Name:Chromite Zirconium Magnetic Separation Process |

| Installation:under technical guidance | Color:Orange or as requested | Market:Africa, Europe, Asia,etc. |

Supply ISO and CE Certified Chromite Zirconium Magnetic Separation Process

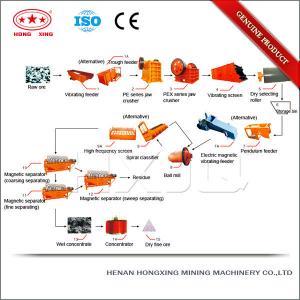

1. Introduction to Chromite Zirconium Magnetic Separation Process

Chromite Zirconium Magnetic Separation Process is suitable for the magnetic separation of the materials whosegranularity is below 3mmsuch asmagnetite, pyrrhotite, calcined ore and ilmeniteand can also be used for removing iron from the materials such as coal, non-metal ore and building material. The magnetic system of magnetic separator is a compound of fine ferrite material and rare earth magnets and the average magnetic induction intensity of the surface of the cylinder is 100~600mT. According to specific need, customers can choose from many kinds of magnetic separators with different surface magnetic intensity such as downstream type, semi-reflux type and reflux-type.

Chromite Zirconium Magnetic Separation Process has the advantages of simple structure, big processing capacity, convenient operation and easy maintenance.

-------------------------------------------------------------------------------------

2. Characteristics of Chromite Zirconium Magnetic Separation Process

1. The coarse separation of lean iron ore after coarse crushing or medium crushing eliminates the barren rocks such as surrounding rock, improves the taste of the iron ore and eases the load of the next procedure.

2. Garnet Hematite Magnetic Drum Separator can be used in the closed circuit firing work for restoring the hematite, and it can separate the rawore that are not fully restored and return it for firing again.

3. In the ceramic industry, magnetic separator can remove the iron mixed in the petuntse and improve the quality of the ceramic product.

4. Magnetic separator can also be used in coal firing, sand making, refractory and other industries that need deironing.

-------------------------------------------------------------------------------------

3.Working Principle of Chromite Zirconium Magnetic Separation Process

The pulp flows into cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or magnet chain which is influenced by the magnetic force inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

-------------------------------------------------------------------------------------

4. Technical Data of Chromite Zirconium Magnetic Separation Process

| Model | Shell diameter (mm) | Shell length (mm) | Shell rotation speed (r/min) | Feeding size (mm) | Processing capacity (t/h) | Power (kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

About us

Delivery

We have developed long and good relationship with many shipping agents. Ocean freight partners are:APL, COSCO, OOCL, CSCL, MSC, etc. and train shipping is also available. The perfect shipping way and best service with lowest price are always provided for customers.

Why Choose Us

1. We Are Factory with 3 Big Production Bases ( NOT Dealer )

All machineries from Henan Hongxing Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service; our production bases are respectively located in Zhengzhou with two bases and Luoyang with one base.

So please buy machine from factory.

-----------------------------------------------------------------

2. Training & Service

1) Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2) Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3) After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

4) In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

-----------------------------------------------------------------

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

-----------------------------------------------------------------

4. We’d like to recommend a suitable type for you and send you a best quotation.

Thanks for your reading and more information can be sent to you by further communication !

| Packaging Detail:Standard export containers, bare main machine, motors and small parts are packed in wooden cases. |

| Delivery Detail:10-15 days after placing the order,some in stock |