superior aluminumn cooling fan for motor

| Place of Origin:Guangdong China (Mainland) | Brand Name:CJC | Model Number:WY64 fan | Type:Motor Fan |

| color:grey | material:aluminum | application:motor parts |

cooling fan

cooling fan features

| material | galvanized steel |

| work flow | stamping→shaping→quality control→packaging |

| life time | 5 years |

| production capacity | 5,000 pcs per day |

| product delivery time | 7 -15 days |

| processing equipments | punching machine |

| test instruments | callipers,projector,general rules,balance machine,height gauge,etc |

cooling fan appreance

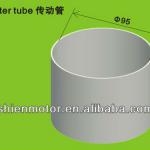

cooling fan demention

| external diameter | φ62±0.2mm |

| inner diameter | 6.35+0.03/0mm |

| concentricity | ≤0.1mm |

| verticality | 0.15mm |

| thickness | 0.5±0.1mm |

| Pulse height | 7.85±0.3mm |

| height | 13.7±0.3mm |

| width | 14.0ERF |

advanced processing equipments:

Surface grinding machine , water grinder, hand grinder, radial drilling machine, drilling machine, line cutting machine , sparks machine, milling machine, etc

progressive test instruments:

Calipers, concentricity gauge, thickness gauge, height gauge, flatness gauge, salt spray test machine, projector, torque gauge, tension meter ,etc

our workshop

we have 5 production lines and 130 production personnels including: high impact group, single shot group, continuous group, rivet joint group, tapping group

our factory

| Founded time | 1997 |

| Registered Place | Shenzhen |

| Management Mode | Production and serving model |

| Factory Area | 8000m2 |

| Main Market | Every city of China, Southeast Asia, South America, Brazil, India |

| Company’s licence | ISO9001:2000 ,UL |

| Company structure | motor department,metal stamping department,shaft department,rubber coatingdepartment,financial sectionandadministration section. |

| Main Products | motor, motor rotor and stator , motor bracket, terminals, motor fan,end cover and other metal stamping parts, mould, shaft, etc |

| Main Service | According to the customer's drawings for mould design ,development and manufacture. |

main advantages

1) we have specialized in manufacturing metal stamping parts for 16 years.

2) we can make molds for most stamping parts according to your drawings or samples.

3) we have serious quality control ,so the product quality is stable.

4) All of our products has meet the ROHS requirements

| Packaging Detail:poly bag for inner, carton for outside or as request |

| Delivery Detail:with 7-15 days after payment |