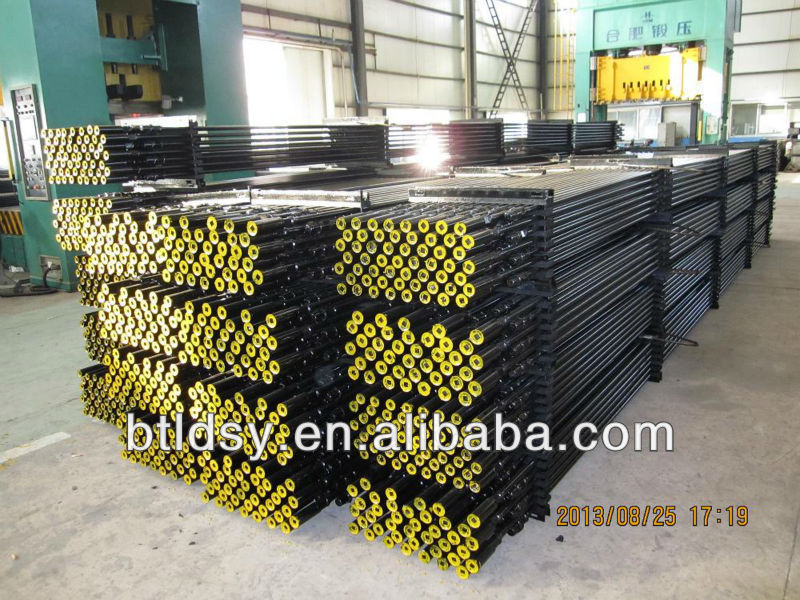

sucker rod

| Place of Origin:Inner Mongolia China (Mainland) | Brand Name:Liande | Model Number:5/8 ", 3/4 ",7/8 ",1 ",1 1/8 ",1-1/4 " | Type:Sucker Rod |

| Machine Type:Drilling Equipment | Certification:API | Material:Chromium Molybdenum Alloy Steel | Processing Type:Forging |

| Use:Well Drilling | tensile strength:90000-173339 Psi | yield strength:60000-115000 psi | reduction of area:45%-60% |

| elongation:10%-13% |

Sucker Rod and Pony Rod

Our Advantages:

1.APICertificate

2.R&D Ability

3.100% Inspection

4.0 Defect

5. Five years' exporting experience

Technical Parameters of Sucker Rod

| SIZE (in) | ROD D.(in) | THREAD D. (in) | LENGTH (ft) | OUTSIDE DIAMETER OF PIN SHOULDER(mm) | LENGTH OF PIN(mm) | LENGTH OF WRENCH SQUARE(mm) | WIDTH OF WRENCH SQUARE(mm) |

| 5/8" | 5/8" | 15/16 | 2 4 6 8 10 25 30 | 31.75 | 31.75 | ≥31.75 | 22.23 |

| 3/4" | 3/4" | 1-1/16 | 38.10 | 36.51 | 25.40 | ||

| 7/8" | 7/8" | 1-3/16 | 41.28 | 41.28 | |||

| 1" | 1" | 1-3/8 | 50.80 | 47.63 | ≥38.10 | 33.34 | |

| 1-1/8" | 1-1/8" | 1-9/16 | 57.15 | 53.98 | ≥41.28 | 38.10 |

Grade and Mechanical Properties

| No. | Grade | Tensile Strength Rel(Mpa) | Yield Strength Rm(Mpa) | Percentage Elongation A(%) | Contraction Percentage Of Area Z(%) |

| 1 | C | 620-795 | ≥415 | ≥13 | ≥50 |

| 2 | K | 620-795 | ≥415 | ≥13 | ≥60 |

| 3 | D | 795-965 | ≥590 | ≥10 | ≥50 |

| 4 | KD | 795-965 | ≥590 | ≥10 | ≥50 |

| 5 | HL | 965-1195 | ≥795 | ≥10 | ≥45 |

| 6 | HY | 965-1195 | —— | —— | —— |

Packaging Type

| Dimention | Length(ft) | Pieces/bundle | Net Weight (KG) | Gross Weight (KG) | Remarks(L×W×H) mm | Adapted Container | Pieces of every Container |

| 5/8" | 25 | 150 | 1930 | 1938 | 7930×550×330 8300×550×330 9440×550×330 | 40'GP/40'OT | 1920 |

| 26 | 150 | 1945 | 1953 | 1920 | |||

| 30 | 150 | 2210 | 2218 | 1690 | |||

| 3/4" | 25 | 100 | 1850 | 1858 | 1345 | ||

| 26 | 100 | 1865 | 1873 | 1334 | |||

| 30 | 100 | 2120 | 2128 | 1174 | |||

| 7/8" | 25 | 80 | 1920 | 1925 | 1039 | ||

| 26 | 80 | 2012 | 2017 | 991 | |||

| 30 | 80 | 2290 | 2290 | 897 | |||

| 1" | 25 | 60 | 1915 | 1923 | 780 | ||

| 26 | 60 | 2006 | 2014 | 744 | |||

| 30 | 60 | 2278 | 2283 | 657 | |||

| 1-1/8" | 25 | 50 | 2044 | 2052 | 609 | ||

| 26 | 50 | 2135 | 2143 | 583 | |||

| 30 | 50 | 2392 | 2398 | 521 |

All the sucker rod and pony rod are strictly manufactured as per API Spec 11B.The manufacturing process as follows:

Raw material magnetic leakage inspection

Raw material straightening

Forging process

Heat Treatment

Shot Peening

Maganetic particle inspection

Thread machingand thread inspection

Packaging

Corrosion-resistant painting

Loading container

Inspection is furnished in every manufacturing process, and we promise that every process is inspected one hundred percently by professional inspectors with precise tools,so the quality can be guaranteed totally.

so,customers can choose different kind of sukcer rod and pony rod according to the certain wells' condition,and we will provide you with professional suggestions regarding different wells' condition and provide you with high quality products and service.

| Packaging Detail:Packaging type: Seay worthy packagingContainer type: 40'OT/40'GPQuantity of every container : 1300 pieces (take 3/4"*25ft as example) |

| Delivery Detail:30 days after PO being singed |