Steel Z Purlin Making Forming Machinery For Building

| Type:Steel Frame & Purlin Machine | Condition:New | Work Pressure:245Mpa | Production Capacity:24 hours |

| Place of Origin:Liaoning China (Mainland) | Brand Name:HT | Model Number:HT-C Model | Voltage:380V |

| Power(W):11kw | Dimension(L*W*H):9000*1500*1200mm | Weight:6T | Certification:CE |

| Warranty:1 year | After-sales Service Provided:Overseas third-party support available | Color:all on your demand | Controlling system:CNC |

| Hydraulic pressure:18-20MPa | Main motor power:11KW | Width of the panel:80-300MM | Thickness of the panel:2.0-3.0MM |

| Material of rollers:45# steel,quenched | Material of cutting blade:Cr12 | The PLC:China brand |

Steel Z Purlin Making Forming Machinery For Building

Main Technical Index

1.Rolling speed: 12-15m/minnot including cutting and punching speed

2.Roller group: 16 groups ,one of which is punched hole

3.Roller material: After finishing the use of steel hardening by Cr12, surface treatment HRC58-62 nigrescence

4.Shaft material: 45 steel after dealing with to enhance the intension of the roller. 56mm

5.Main motor power:5.5Kw

6.Hydraulic station power:5.5Kw

7.Hydraulic pressure: 20Mpa

c purlin machine

roll forming machine

c purlin roll forming machine

Profile(jist for reference)

Material:

1.5 mm Minimum Thickness, 3.0mm Maximum Thickness

The 2.5 mm thickness raw material for inspection, in common use

Ex Cold Rolled Coil, Galvanized Coil, Tension grade: 245Mpa

Manual un-coiler

Feeding width: max. 500mm;

Capacity: Max. 5ton

Hydraulic punching&Cutting device

Stop to Punching, Stop to Cutting, post punch, Post Cut, no slug

Hydraulic motor: 5.5Kw

Cutting tool material: Cr12, Heat treatment

PLC Control System(English and Chinese Exchange)

Control the quantity & cutting length automatically

Combined with: PLC, Inverter, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

The line consists of decoiler, sheet guiding equipment, roll forming section, cutter, supporter, hydraulic system, control system. The roller shutter which made by this machine have neat external appearance, even ripples, high utilization and strong strength.

2. Technical Parameters

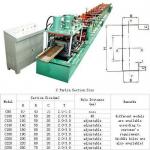

| No | Item | Parameter | Note | |

1 | Suitable Material | Type | Steel sheet | |

| Roller Shutter | Thickness: 0.7-1.0 mm | |||

| 2 | Product Specifications | Detail as the attached drawing | ||

3 | Power Requirement | Type | 380V/3PH/50HZ | |

| Main motor power(KW) | 3 | |||

| Cutting power(KW) | 2.2 | |||

| 4 | Forming Speed(m/min) | 12-15 | ||

| 6 | Forming Stand | 12 | Depend on actual design | |

| 7 | Forming Shaft Diameter(mm) | 56 | Depend on actual design | |

| 8 | Type of Cutting | Roll-formed and length-set cutting | ||

| 9 | Control System | Mitsubishi PLC and inverter | ||

| 10 | Run Out Table | 2mX3 | ||

| 11 | Installation Dimension(m) | 8X1.5 | Without the panel length | |

| 12 | Total Weight(T) | 8 | Depend on actual design | |

SERVICE AFTER SALE

1)In correct operation & maintaining, the machine is guaranteed for one year since leaving our factory excludes the electric elements.

2)If needed, our engineer can go to the buyer’s factory to install and debug the machine.

| Packaging Detail:Naked,one 40GP can load the machine and all accessories... |

| Delivery Detail:30 days since receive the advanced payment |