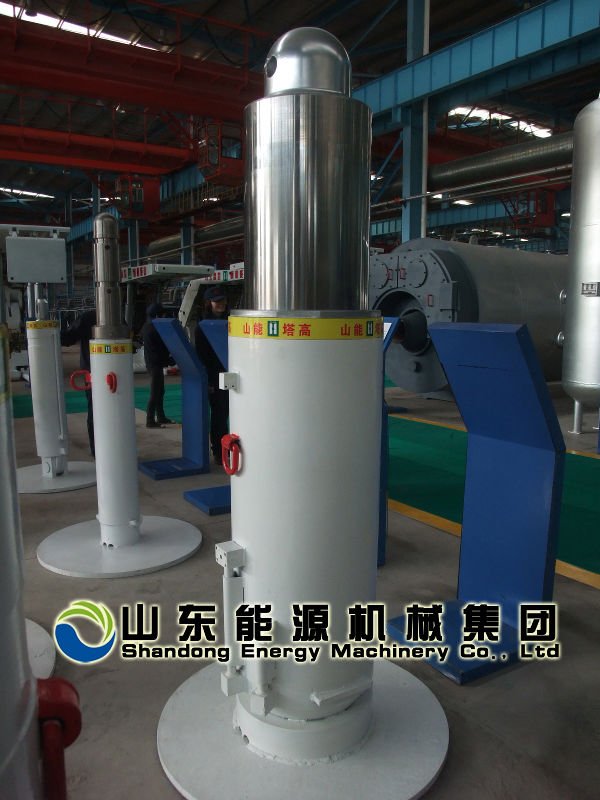

stainless steel column

| Place of Origin:Shandong China (Mainland) | Brand Name:SN | Type:Hydraulic Support | Machine Type:support equipment |

| Certification:DIN | Material:Stainless Steel | Processing Type:Casting | Use:Coal Mining |

| feature:corrosion-resistant |

stainless steel column:

I. Laser technology

Laser Cladding, Laser Alloying and laser quenching are the main laser technology of our company.

Laser Cladding is a new kind of surface modification technology, the high power densities laser beam fused the cladding material and the surface together to be a cladding layer.

II. Laser cladding stainless steel column

Laser cladding stainless steel column is developed for the new mining hydraulic support, with high abrasion resistance, high corrosion resistance, long service life and 5-years maintenance free.

The sealing parts are all turning processed with no mold, import material, with high sealing performance, high resistance to pressure, high abrasion resistance, aging resistance and high precision structure dimension etc.

The traditional electroplating column is surface chrome plated to be anti-rust and anti-corrosive, but for the weak abrasion resistance of the chome layer, once the electroplated layer is partly damaged, the service life will be 1-1.5 years. After two or three times maintenance, the column can't be used again.

The Laser cladding stainless steel column is coated with the stainless steel alloy layer to improves the rigidity, the binding force can be higher than 310MPa with the layer, and the surface hardness can be HRC 45-50, if be partly damaged, only need to repair the damaged part. Also the column can be recycled.

No. | Style | Comparison | |||

| Manufacturing Technology | Service life | Maintenance | Adhesion strength | ||

| 1 | Traditional electroplating column | Plating, pollution of environment | Maintenance every 1-1.5 year,out of service 2-3 maintenances | Local damage to the plating, overall maintenance. External diameter becomes smaller after repairation. | Physical combination of plating layer and the substrate, low adhesion strength, easy to drop |

| 2 | Laser cladding stainless steel column | Laser-cladding, green production | Wear/corrossion-resistant,with service life 5-6 times than domestic products | Part damage of the cladding layer, part maintenance to reduce cost and time with recycling use. | Cladding metallurgical bonding with substrate, strong adhesion, with HRC45 |

12000 tests by State Coal Supporting Equipment Quality Supervision Inspection Center show that all properties such as enduration, sealing and overflow have achieved standard, with 5-year maintainence-free. The product won national utility model patent(ZL 2008 2 0026688.0) in May.2009, the first in China to reach international advanced level.The product has been sucessfully used in hydraulic support with supporting resistance 11000KN,15000KN,17000KN,9000KN.

1,Significantly enhance hydraulic support quality.To improve hydraulic system stablity, without any leakage, adapting to various acid-base water environment and continous use in the underhole.

2,Significantly simplify hydraulic support maintenance. No need to repair column ensures hydraulic support need not repair disassembly, to simplify the maintenance process which can be finished in the underhole or minefield.

3,Move of working face is more convenient. The enhancement of hydraulic support helps working face not to gug repair.

4,To reduce cost of remote mine. The reduction of repair and transport cost cut the cost.

5,Appropriately lengthen the service life.Hydraulic support installed with new stainless steel column, without disassemble transpot has a longer service life.

6,Decrease the input of hydraulic support.To reduce numorous cost by cutting expense of buying new equipment to replace and helping to recover the property with remanufacturing technology.

| Packaging Detail:according to customers' requirements |

| Delivery Detail:10-30 days |