STA W type Molybdenum disilicide heater MoSi2 heating element

| Condition:New | Type:Air Heater | Power Source:Electric | Place of Origin:Henan China (Mainland) |

| Brand Name:STA | Model Number:MoSi2---001 | Dimension(L*W*H):400x400x450 | Weight:1.5kgs |

| Voltage:220v | Power(W):1500W | Certification:CE proved | Warranty:8 months |

| After-sales Service Provided:Overseas service center available | size:customized | deliver:By DHL,TNT ,Sea ,Air | deliver time:short |

| color:gray |

STA universe group CO .,LTD as a professional manufacturer of Molybdenum disilicide heater MoSi2 heating element and accessories with many years !!

The General Descrioition Of Molybdenum disilicide heater MoSi2 heating element as below :

1. Molybdenum disilicide heater MoSi2 heating element is a kind of resistance heating element basically made of high pure Molybdenum Disilicide.

2. Molybdenum disilicide heater MoSi2 heating element

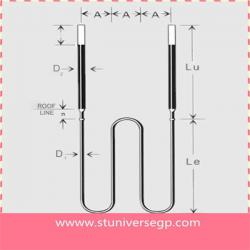

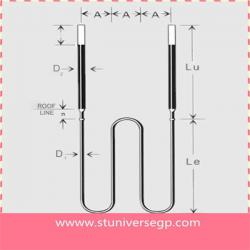

1) Main type :U, W ,UL, WL, Rod . Material grade :M1700,M1800,M1900.

2) Standard dimension (mm):3/6,4/9,6/12,7/14,9/18,12/24.

3.physical property

| volume density | 5.5~5.6g/cm³ | bend strength | 5.5~25kg/cm² |

| vickers-hardness | (hv)570kg/mm² | porosity rate | 7.4% |

| water absortion | 1.2% | hot extensiblity | 4% |

4.Recommend Surface load Molybdenum disilicide heater MoSi2 heating element

| Furnace Temp (C ) | 1400 | 1500 | 1600 | 1650 | 1700 |

| Surface load of hot zone(w/cm2) | <18 | <15 | <12 | <10 | <8 |

5.the dimension list :

6.The influence of operation temperature on the heater surface in a different atmosphere

Atmosphere | The Maximum Using Temperature of Element | ||

| 1700 Grade | 1800 Grade | 1900 Grade | |

| NO2,CO2,O2,Air | 1700°C | 1800°C | 1850°C |

| He,Ar,Ne | 1650°C | 1750°C | 1800°C |

| SO2 | 1600°C | 1700°C | 1800°C |

| CO,H2 | 1500°C | 1600°C | 1700°C |

| WetH2 | 1400°C | 1500°C | 1650°C |

| DryH2 | 1350°C | 1450°C | 1600°C |

6.It can be widely used in such applications as sintering and heating treating of ceramic ,magnet ,glass,metallurgy ,refractory,ect.

7.Installation of elements

1)vertically hanging

Under normal temperature,MoSi2 ,element is very brittleness,while under high temperature it is plasticity.So,the better way for installation if the UShape element is to hang it vertically,to the furnace top through the support clamping chuck H.The aim of such way is to avoid putting the mechanical stress directly to the element heat-generating end ,or the element will easily be broken.

2) support clamp

Support clamp are applied to 9/18 and 6/12 two kinds of elements respectively. the support clamp supports the whole weight of the element and the position of the element is also determined by it .therefore ,it must be installed carefully to assure that the element it veryically hungin order to prevent the element from being over heated locally,the taper part of the element lower end must put into the furnace chamber.

Products show :

Clamp :

Package details :

If you have any need ,please contact me in time .Welcome to visit our website :www.stauniversegp.comWaiting for your good news ,thanks in advance !

| Packaging Detail:in wooden box with foam board or in standard export package . |

| Delivery Detail:10~25 days after receiving your payment |