Spring hydraulic cone crusher

| Place of Origin:Shanghai China (Mainland) | Brand Name:Jianye | Model Number:JYB/JYD series | After-sales Service Provided:Engineers available to service machinery overseas |

| Application:limestone,CACO3,ore,barite,granite,etc all kind of mineral stone | Capacity:12-800t/h | Max feeding size:300mm | Price:negotiable |

| Guarantee:one year excluding wearing parts | Certificate:ISO9001:2000 | Spare parts:supply for whole year | Installation:under our engineer's guide |

| After-sale service:for whole using life | Color:as per your requirement |

Cone Crusher Description

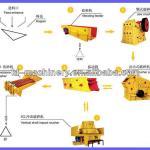

Cone crusher is the earliest cone crusher appearance in the world, and they are used widest and larger quantity crusher machine at present. With the improvement of the series of cone crusher, their structure is more perfect and the technology parameter is more advanced, so this series of cone crusher have excellent performance in the aspects of manufacture, installation, use and maintenance etc. Type of the crushing cavity is decided by the application of the ores.

The standard spring cone crusher is used for intermediate crushing; the medium spring cone crusher is used for fine crushing; and the short head spring cone crusher is used for super thin crushing. spring cone crusher is widely used in industries like metallurgy, construction, road building, chemistry etc, to crush many kinds of mid-hard or hard rocks and ores such as iron ore, limestone, granite, basalt, quartz etc.

Cone CrusherWorking Principle

The cone crusher crushes materials by the working surface between the movable cone and fixed cone. So it is more advanced and efficiency efficient than jaw crusher. The movable cone is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and fimbriated gear, and the wheel of the conveyor belt is driven by motor through v-belts. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks in the spring cone crusher are grinded into pieces, when the movable cone leaves, grinded materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size of the spring cone crusher is determined adjusted.

Cone Crusher Technical Parameters

| Model | Head Diameter(mm) | Max Feeding Size(mm) | Output Size(mm) | Capacity(t/h) | Power of Motor(Kw) | Overall Dimensions(mm) |

| JYB600 | 600 | 65 | 12-25 | 40 | 30 | 2234×1370×1675 |

| JYD600 | 35 | 3-13 | 12-23 | |||

| JYB900 | 900 | 115 | 15-50 | 50-90 | 55 | 2692×1460×2350 |

| JYZ900 | 60 | 5-20 | 20-65 | |||

| JYD900 | 50 | 3-13 | 15-20 | |||

| JYB1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 2590×1878×2844 |

| JYZ1200 | 100 | 8-25 | 42-135 | |||

| JYD1200 | 50 | 3-15 | 18-105 | |||

| JYB1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 3910×2894×3809 |

| JYZ1750 | 185 | 10-30 | 115-320 | |||

| JYD1750 | 85 | 5-13 | 75-230 | |||

| JYB2200 | 2200 | 300 | 30-60 | 500-800 | 280/260 | 4622×3302×4470 |

| JYZ2200 | 230 | 10-30 | 200-580 | |||

| JYD2200 | 100 | 5-15 | 120-340 |

More information, please visit our web in English:

http://www.mineral-grinder.com

| Packaging Detail:Export Package standard. Large part is non-packed, small parts are in wooden/ metal box package. |

| Delivery Detail:15-30 days |